Driven by the global energy structure transformation and the “dual-carbon” goals, industrial energy storage technology is evolving from a simple energy storage tool to a core node in the smart manufacturing system. The accompanying fully Automated Solar Panel Cleaning Systems, with its intelligent operation and maintenance capabilities, is becoming a key breakthrough in improving the efficiency and extending the lifespan of energy storage equipment. The following analysis explores this from the dimensions of technological innovation and commercial value.

1. Five Cutting-Edge Application Scenarios for Industrial Energy Storage

1.1 Smart Grid Peak Shaving

In 2024, a Chinese steel group deployed a 200MW/800MWh iron-chromium flow battery energy storage system, which responds to grid load fluctuations in real-time, saving over 120 million yuan in electricity costs annually. The accompanying drone inspection system reduced fault response time from 6 hours to 15 minutes.

1.2 Microgrid Energy Management

A Southeast Asian rubber industrial park adopted a “photovoltaic + sodium-ion battery” microgrid, combined with AI power prediction algorithms, enabling 24-hour continuous production. The fully automated cleaning robot removes dust from photovoltaic panels daily, increasing power generation efficiency by 18%.

1.3 Heavy Industry Energy Saving Transformation

A German automotive factory integrated a supercapacitor energy storage system to recover braking energy in the stamping workshop. Combined with a laser cleaning device that continuously removes the oxide layer on the capacitor surface, the energy conversion efficiency remains stable at over 92%.

1.4 Data Center Emergency Systems

Microsoft’s Azure data center adopted an immersion liquid-cooled energy storage module, paired with pipeline self-cleaning technology, ensuring 99.999% power supply reliability during the 2024 typhoon season, while reducing single-rack maintenance costs by 40%.

1.5 Distributed Energy Systems

Japan’s 7-Eleven convenience store network deployed modular zinc-air energy storage units, which maintain 85% charge-discharge efficiency in humid environments through cloud-controlled nano-coating cleaning technology.

2. Four Core Advantages of the Fully Automated Solar Panel Cleaning Systems

2.1 Efficiency Revolution

- Ultrasonic dust removal devices can increase lithium battery cooling efficiency by 30%.

- Wall-climbing robots enable 360° non-destructive cleaning of flow battery pipelines.

- Machine vision recognition systems accurately locate electrolyte crystallization areas.

2.2 Cost Control

| Traditional Mode | Automated Cleaning System |

|---|---|

| Manual inspection: ¥1200 per session | Single cleaning cost: ¥80 |

| Annual downtime loss: ¥860,000 | Failure rate reduced by 72% |

2.3 Safety Upgrade

Millimeter-wave radar monitors dust concentration inside energy storage cabinets in real-time, combined with negative pressure adsorption technology, reducing the risk of thermal runaway to 0.03 incidents per 10,000 hours, far exceeding national standards.

2.4 Intelligent Operation and Maintenance

- Blockchain technology records each cleaning parameter.

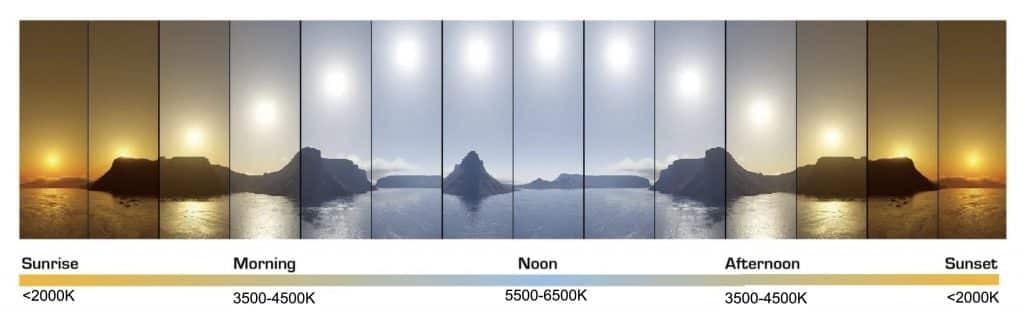

- Digital twin systems simulate cleaning cycles under different climate conditions.

- Self-learning algorithms optimize cleaning agent ratios.

3. Technological Synergy Creates Incremental Value

When industrial energy storage meets fully automated cleaning, it is driving three major business model innovations:

- Energy Storage as a Service (EaaS): A complete solution lease including cleaning and maintenance.

- Carbon Asset Appreciation: The energy efficiency improvements contributed by the cleaning system can be converted into CCER carbon credits.

- Equipment Health Bank: A residual value assessment system based on cleaning data.

Recommended Products – Todos Automatic Solar Panel Cleaning Robot

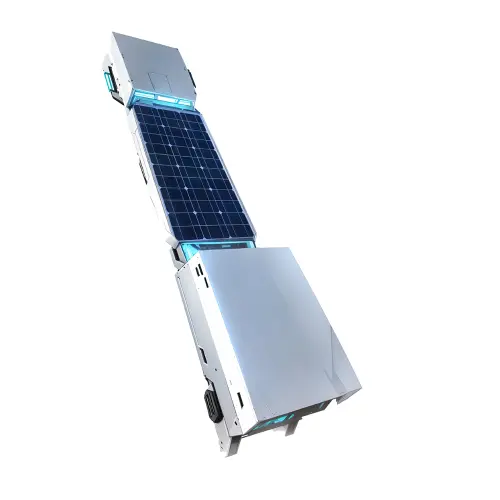

1. Automatic Solar Panel Cleaning system

- Cleaning times: once a day;

- Cleaning effect: more than 98%;

- Cleaning method: dry sweep, No need for water. The water sweeping function needs to be customized.

It is very suitable for large power station maintenance, especially for large power generation in deserts, cities, and high pollution areas.

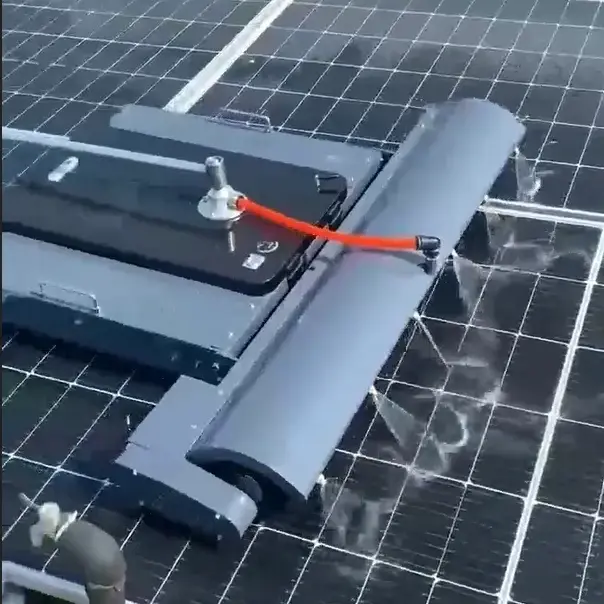

2. Remote Control Solar Panel Cleaning Robots

- Cleaning method: water washing, dry cleaning;

- Cleaning effect: more than 98%;

- Operation mode: semi-automatic;

This is the most commonly used style of cleaning company, easy to transport and carry.