Street Light Distribution Analysis – How to Meet Your Road Lighting Standards!

This is a requirement for road lamp design.

| Item Name | Route Code | Road Width (m) | Surface Type | Lamp Configuration | Number of Lamps | Lamp Height (m) | Lamp Spacing (m) | Angle (°) | Length of Lamp Arm (m) | Distance Between Lamp and Road (m) | Illuminance (1m) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Route 1 | M5 | 7m | CIE C2 (Calculated Humidity) | Unilateral Lamp | 0.8 | 12 | 40 | 0 | 0 | 0.75 | 8000 |

| Route 2 | M3 | 14m | CIE C2 (Calculated Humidity) | Bilateral Lamp | 0.8 | 10 | 40 | 0 | 0 | 0.75 | 8000 |

Now, based on the above conditions, we need to select the light distribution for the lamps and verify it.

First, let’s analyze the road conditions.

For Route 1, with a road width of 7m, this should be a two-lane road with unilateral lamp arrangements, pole spacing of 40m, and pole height of 7.5m.

For Route 2, with a road width of 14m, this should be a four-lane, bidirectional road with bilateral lamp arrangements, pole spacing of 40m, and pole height of 9m.

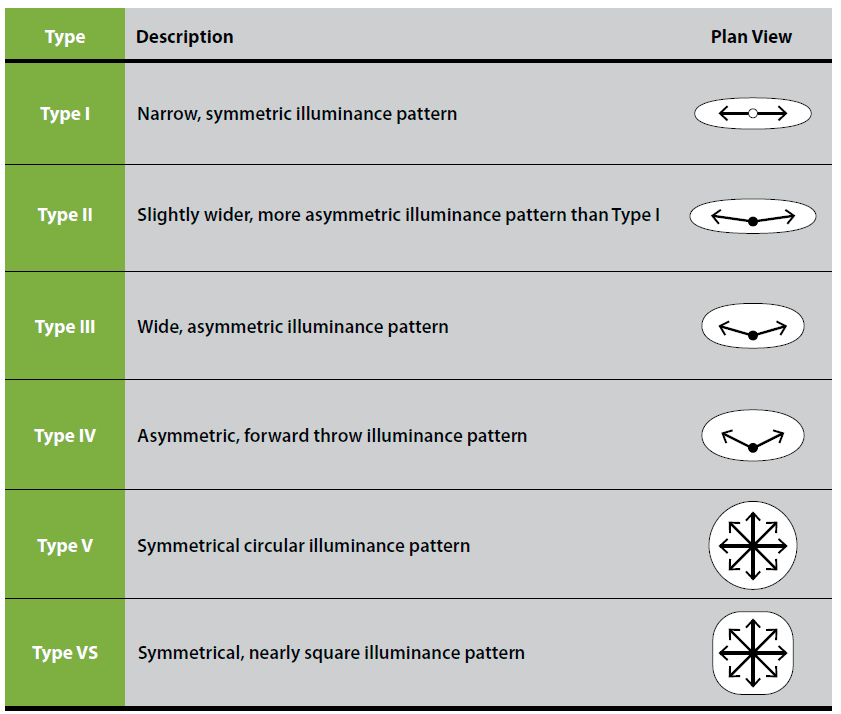

Based on these road conditions, we proceed with the selection of light distribution, referencing IESNA’s categorization of street lamps.

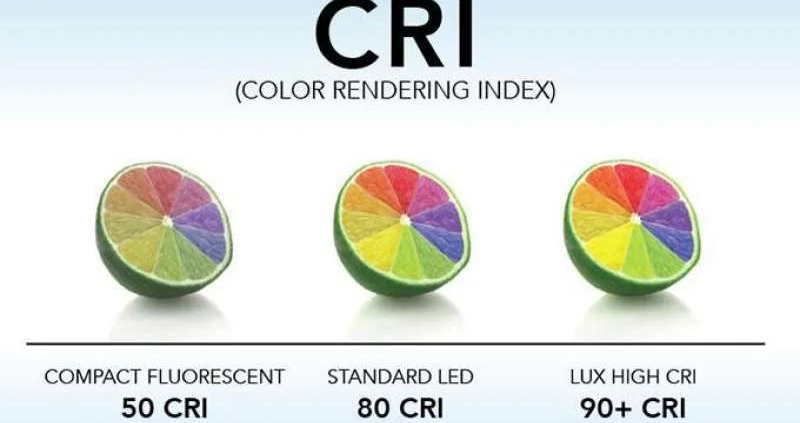

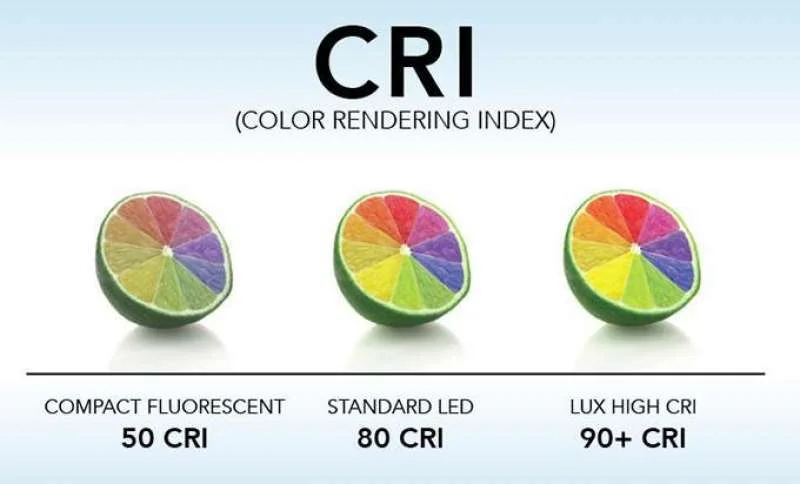

↑ IESNA Street Lamp Classification, North American Lighting Manual 10th Edition

For one to two-lane roads, we typically choose Type II street lamps. Type I is suitable for paths and sidewalks, while Type III applies to main highways.

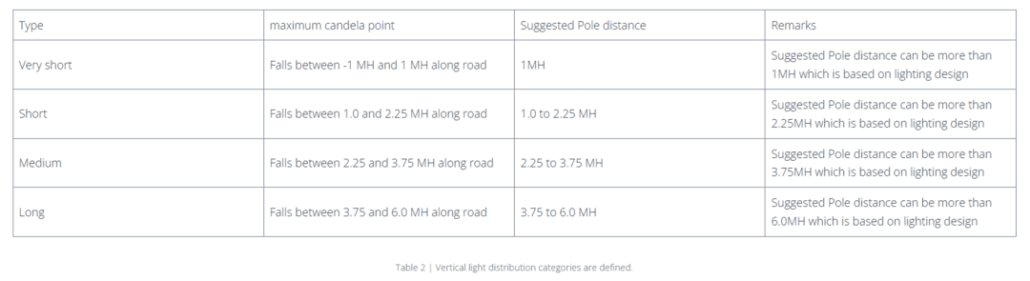

We can refer to the following rules based on road width.

As per the above table, we should select the Type II L distribution. However, considering the distance of 0.75m between the lamp and the road as specified in the road conditions, we will adjust our pole spacing slightly and choose Type II M or S distribution.

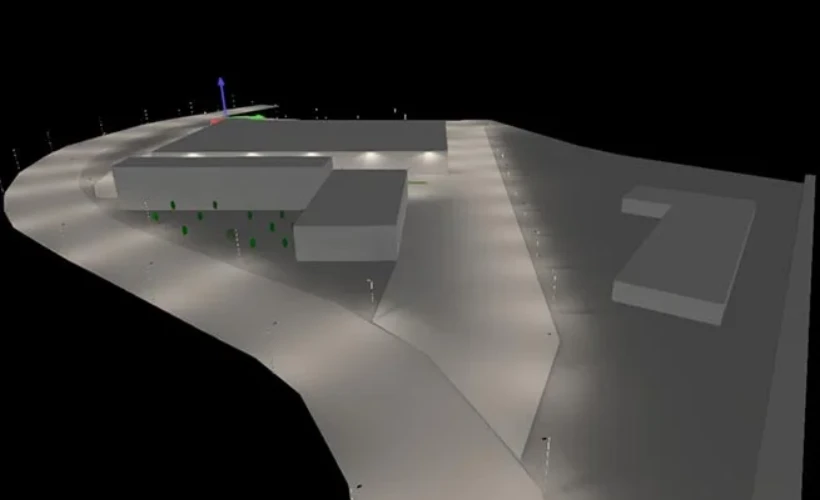

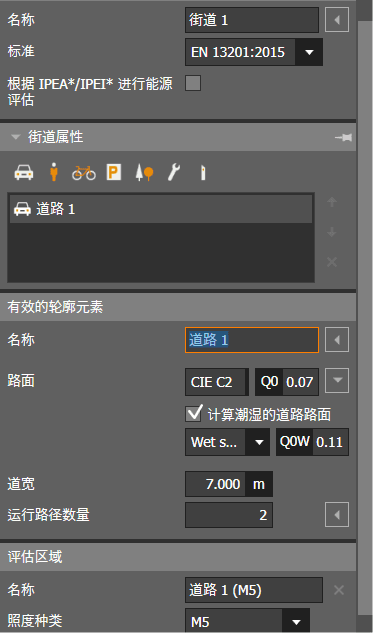

Let’s begin testing Route 1 by setting the road conditions in DIALux evo (we avoid DIALux4.13 as it does not support the EN13201:2015 standard necessary for selecting the new standard).

Here, we need to select the surface type as CIE C2 and check the option for calculating wet road surfaces, choosing W1.

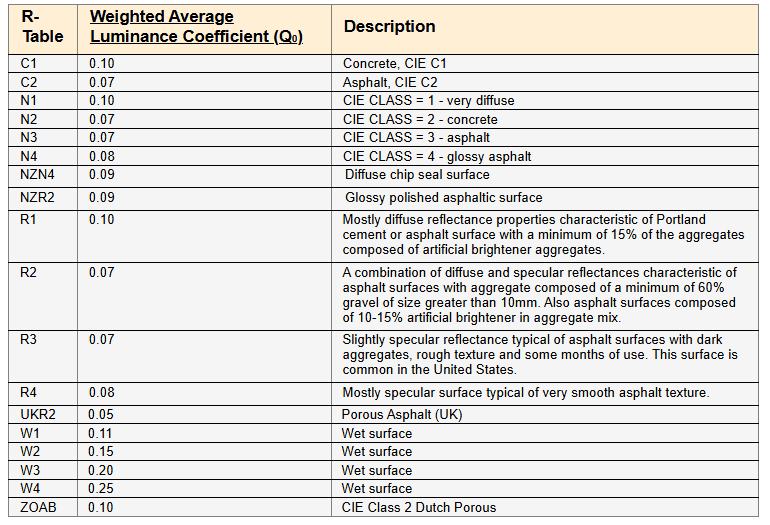

The CIE C2 surface corresponds to asphalt, similar to the reflectivity of our traditional R3. Further explanation of the codes is provided below:

With the road conditions set, we can select the light distribution for verification calculations.

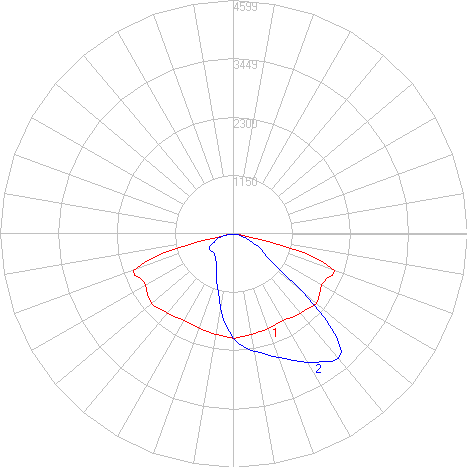

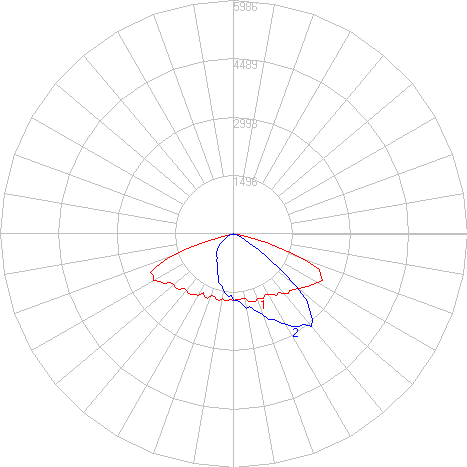

We are going to select a Type II S distribution for verification.

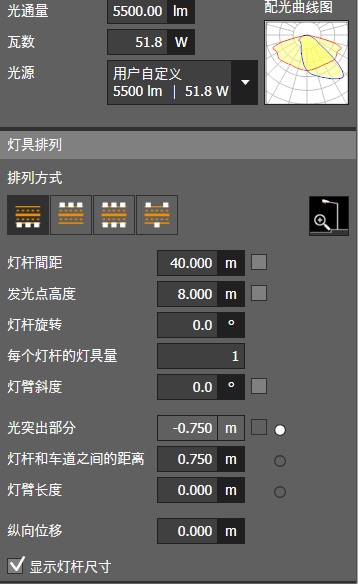

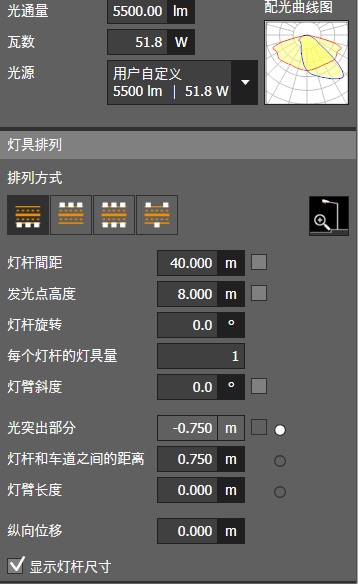

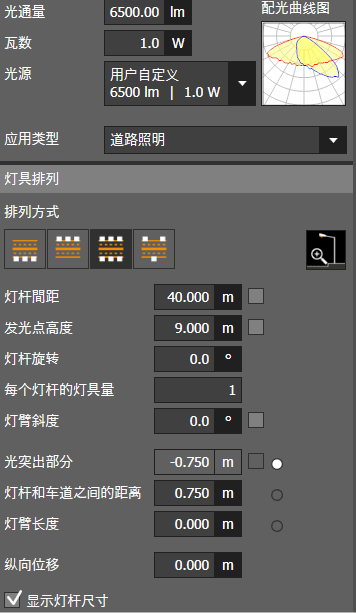

Set the lamp arrangement conditions and configure the lamp luminous flux to the required 5500lm.

Verification Results

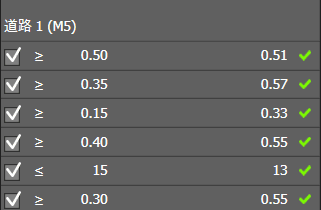

The results were not satisfactory; the road brightness uniformity was below the standard requirement of 0.5cd/m². However, both Uo and Uow, as well as Ul, significantly exceeded the standard values.

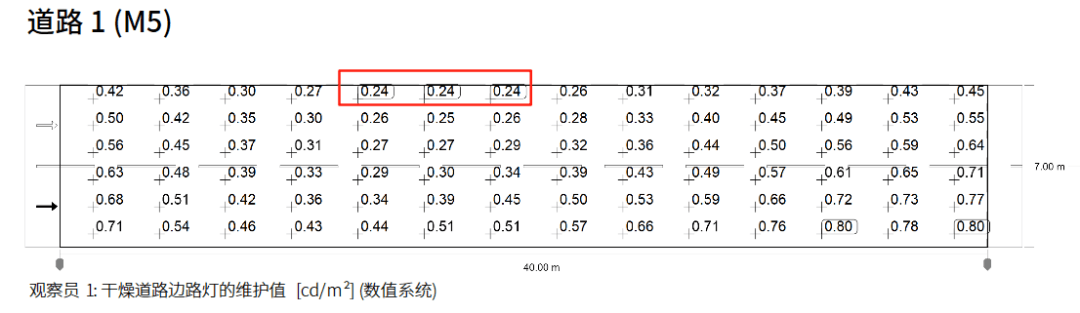

We can conclude that the distribution might be slightly inadequate, but where exactly is it lacking? We need to analyze the brightness calculation grid.

By analyzing the calculation grid above, we found the minimum value, which is lower between the two lamp poles. This indicates that the light distribution needs to be strengthened at both ends, so we will directly choose Type II M distribution for our calculations.

Verification Results

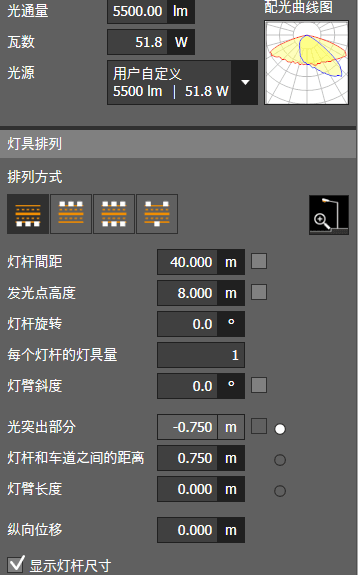

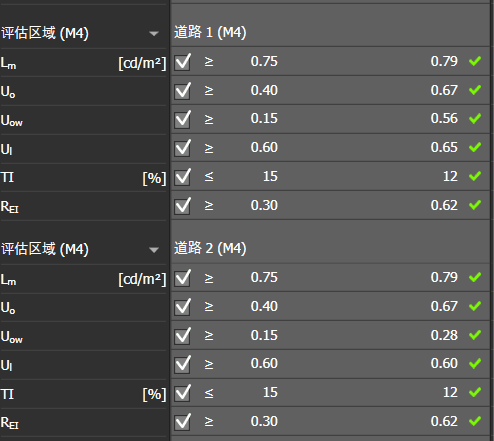

The results are all satisfactory, indicating that this light distribution can meet client requirements under the specified 5500lm luminous flux.

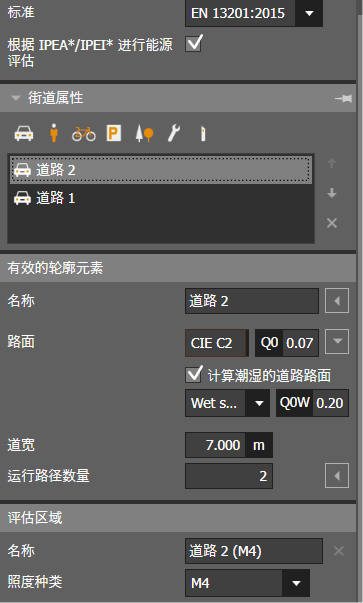

Next, let’s look at Route 2 and set the road conditions: a four-lane, bidirectional road, M4 standard, calculated wet surface.

The road conditions for Route 2 are essentially the same as Route 1, except it’s a four-lane bidirectional roadway with bilateral lamp arrangements, upgraded by one level.

We will again choose Type II M distribution for arrangement.

Verification Results

Both sides met the conditions, indicating that this distribution can satisfy client requirements under the specified 6500lm luminous flux.

Through this analysis, it is evident that there are patterns to follow when selecting light distribution for street lighting. Whether choosing existing products or developing new distributions, one can design according to these rules and then identify defects through calculation results, making targeted modifications accordingly.