What are the definition and working principle of light towers

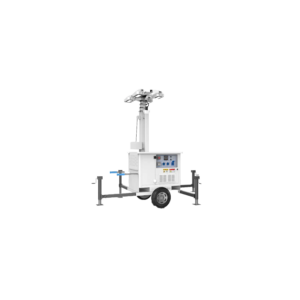

- Concept and Function: Light towers are integrated high-level lighting systems, typically incorporating lighting fixtures, telescopic masts, power sources (generators or electrical supply), control, and safety systems. They provide high-intensity, coverable illumination for nighttime or low-light work conditions.

- Application Scenarios: Common applications include construction sites, outdoor events, emergency rescue, mining areas, and remote oil and gas fields, emphasizing on-site safety and improved operational efficiency.

What are the components and working process of lighting towers?

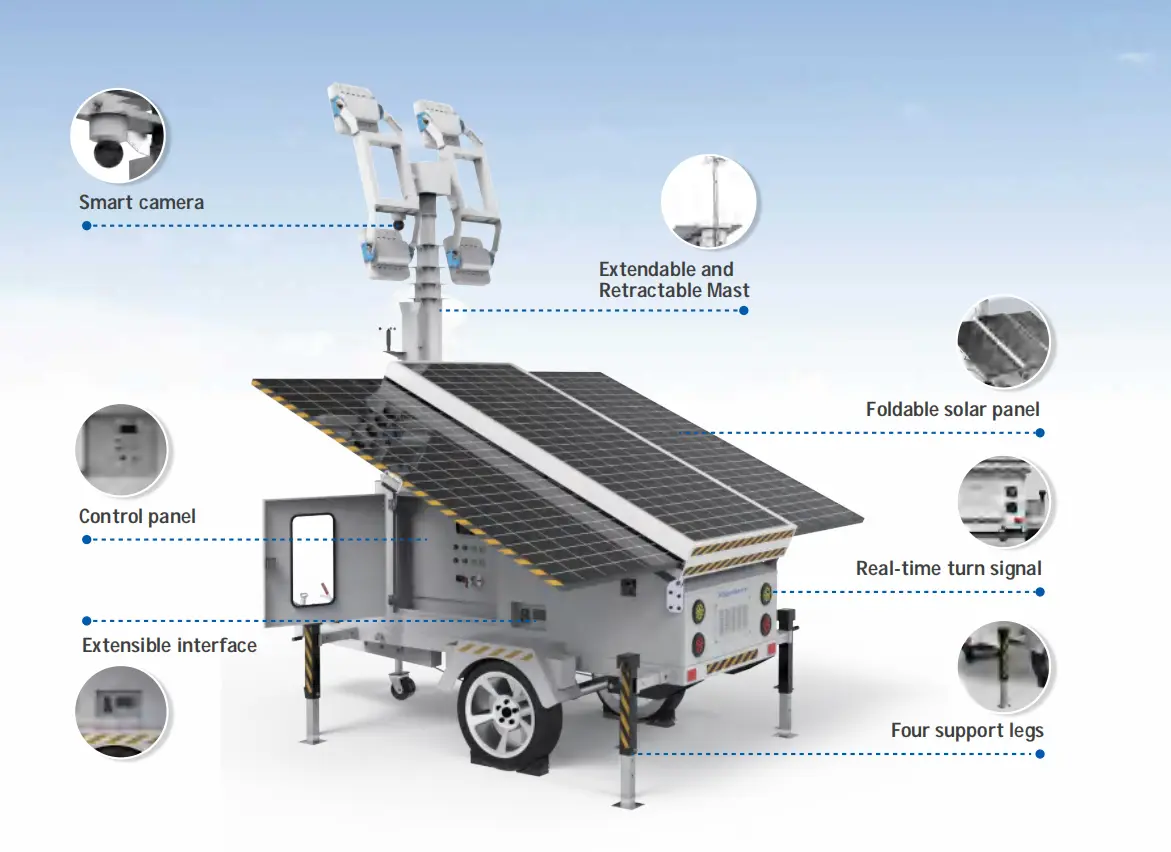

- Main Components: Lighting fixtures, masts/towers, power sources (diesel generators or grid/battery packs), lifting and positioning mechanisms, control panels, tires/support legs, and shock/wind-resistant designs.

- Working Principle: On stable supports and ground foundations, masts rise to the designed height, and fixtures illuminate. If generator-driven, the engine starts to provide power, and the entire system achieves lighting distribution and safety monitoring through the control unit.

What Key Indicators Are Critical When Selecting a Light Tower?

Key Technical Indicators (Core Keywords: Lumens, Lux, Mast Height, Generator Power, Number of Fixtures)

- Illumination Requirement (Lux): Lighting intensity typically ranges from 20 to 100 lux, depending on the application scenario.

- Construction Sites: Minimum of 50 lux.

- Sporting Events: Above 100 lux.

- Mining Operations:

- General Lighting: 50 to 100 lux.

- Fine Work Areas (e.g., drilling, post-blast inspections): 100 to 150 lux.

- Roadways: Minimum requirement of 20 to 50 lux.

- Emergency and Disaster Rescue Lighting Requirements:

- Emergency Command Centers: Minimum of 100 lux.

- Post-Disaster Rescue (e.g., search and rescue after earthquakes or floods): At least 150 lux.

- Evacuation Shelters and Gathering Points: Should be maintained at 50 to 80 lux.

- Drilling Platforms:

- General Lighting: 100 lux.

- Critical Operation Areas (e.g., drilling heads, tool changes): 150 lux.

- Oilfield Pipelines and Storage Areas: Minimum requirement of 50 lux.

- Mast Height:

- Illumination Requirement (Lux): Lighting intensity typically ranges from 20 to 100 lux, depending on the application scenario.

Height Range: Common mast heights range from 3 meters to 12 meters. Taller masts (10 meters and above) can cover a wider area.

- Power Configuration:

Diesel Generator Capacity: Typically ranges from 3 kW to 10 kW (approximately 4 HP to 15 HP). Luxman offers a 20 kW diesel generator for higher brightness lighting needs.

Direct Power Supply: If using a power supply, ensure stable power output. Redundant emergency power should be considered to handle unstable power conditions.

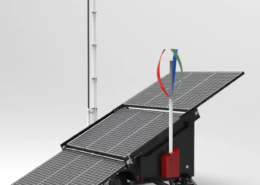

Hybrid Energy: Luxman provides solar, wind, diesel, and grid hybrid models of light towers.

- Type of Fixtures:

LED vs. Traditional Light Sources:

LED Fixtures: Higher energy efficiency, lifespan of 25,000 to 50,000 hours, lower maintenance frequency, and approximately 50-80% lower power consumption than traditional fixtures. Each fixture outputs 2000 lumens with power consumption of around 20-40W.

Traditional Fixtures (e.g., metal halide): Shorter lifespan (usually 2,000 to 15,000 hours), higher power consumption, and higher maintenance costs.

- Noise and Emissions:

Noise Levels: Noise levels for mobile lighting towers typically range between 55 dB and 75 dB (depending on model and power; Luxman’s light towers operate below 55 dB). The noise should meet the following standards:

Urban and Residential Areas: Should be below 60 dB to comply with regulatory requirements and reduce disturbances to nearby areas.

Industrial Areas: Acceptable general noise levels range from 70 dB to 75 dB, but for long-term operation sites, it should be based on specific noise control policies.

What are the Best Styles of Mobile Lighting Towers?

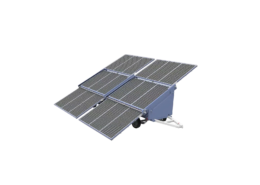

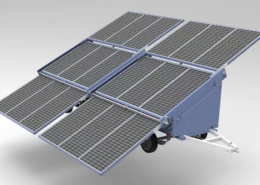

- Small Lighting Tower — Maximum Height: 6 meters; Coverage Area: ~750 square meters; Light Output: ~33,000 lumens; Illuminance: 44~132 Lux; Battery Pack: ~9.6 kWh; Operating Time: ~28.8 hours (depending on brightness); Applicable Scenarios: construction sites, general sporting events, general lighting for mining operations, roadways, evacuation shelters, general lighting for drilling platforms, oilfield pipelines and storage areas.

- Medium Lighting Tower — Maximum Height: 9 meters; Coverage Area: ~1,500 square meters; Light Output: ~66,000 lumens; Illuminance: 44~132 Lux; Battery Pack: ~14.4 kWh; Operating Time: ~20 hours; Applicable Scenarios: construction sites, general sporting events, general lighting for mining operations, roadways, evacuation shelters, general lighting for drilling platforms, oilfield pipelines and storage areas.

- Large Lighting Tower — Maximum Height: 12 meters; Coverage Area: ~2,200 square meters; Light Output: ~198,000 lumens; Illuminance: 90~396 Lux; Battery Pack: ~28.8 kWh; Operating Time: ~20 hours; Applicable Scenarios: general lighting for drilling platforms and critical operation areas, emergency and disaster rescue, general lighting for mining operations and fine work area lighting, medium and small sporting events.

How to Determine Needs for Mobile Light Towers Based on Scenarios?

- Construction Sites: Typically require at least 50 lux to ensure safety. Small to medium models are recommended.

- Sporting Events: Aim for above 100 lux, with stadiums exceeding 200 lux, to meet high visual standards. A large model is recommended.

- Mining Operations:

- General Lighting: Required at 50 to 100 lux for clear visibility of tools, equipment, and surroundings, to reduce accident risks; small to medium models are preferable.

- Fine Work Areas: Suggest increasing to 100 to 150 lux for detailed monitoring and operations; a large model is recommended.

- Roadways: Minimum requirement of 20 to 50 lux to ensure safe passage for transport vehicles and pedestrians; small model can be selected.

- Emergency and Disaster Rescue Lighting Requirements:

- Emergency Response Scene: Command centers require at least 100 lux to ensure clear information transmission and accurate command decisions; medium to large models are recommended.

- Post-Disaster Rescue: At least 150 lux for quick search and identification of rescue persons, assessment of damage, and provision of aid; large models are necessary.

- Evacuation Shelters and Gathering Points: Should be maintained at 50 to 80 lux, medium to small models can be selected.

- Drilling Platforms:

- General Lighting: Required at 100 lux for safe operations and equipment maintenance.

- Critical Operation Areas: Suggest increasing to 150 lux for high-precision operations and inspections; recommend large models.

- Oilfield Pipelines and Storage Areas: Minimum requirement of 50 lux to ensure visibility for inspections and emergency responses to quickly identify leaks or other safety hazards; small to medium models can be chosen.

How To Maintenance and Troubleshooting Points for Lighting Towers

1. LED Module Replacement Cycle

- Basic Principle: Replace when light output decreases to below 80% of original brightness or reaches manufacturer’s specified lifespan, evaluated against actual environmental conditions.

- Fixed Replacement Interval: (Reference values based on “operating hours/year usage”):

- Regular environment, cleaner locations: 50,000–75,000 hours, approximately 5–8 years (if used infrequently, calculated based on actual years).

- Dusty, high temperature, high humidity, coastal/salt spray areas: 25,000–40,000 hours, approximately 3–5 years.

- Extreme environments (high humidity, dirt, frequent temperature fluctuations): 20,000–30,000 hours, approximately 2–4 years.

- Auxiliary Judgment:

- If brightness drops by about 20-30% or color temperature/color rendering decreases significantly, replace early.

- If components degrade causing driver failure, heat management failure, etc., evaluate whether to replace fixtures and driver modules concurrently.

- Note:

- In practice, if there are multiple fixtures on the same assembly, prioritize replacing the modules showing the fastest light depreciation.

- Different manufacturers have different module lifespan curves; prioritize following the lifespan indicators and maintenance suggestions provided by manufacturers.

2. Regular Maintenance Points (Periodic)

- Daily (Per Shift/Daily)

- Check and confirm fuel/power status is normal, and gauge displays are functional.

- Exterior Cleaning: Remove dirt from fixture surfaces and lenses to maintain stable light output.

- Tower and Support Stability Check: Ensure bolts are tightened, support legs are intact, and ground foundation shows no displacement.

- Periodic (Divided by Timeframe for On-site Planning)

- Weekly/Per Shift: Check that fixture connections and plugs are intact, and that wire insulation is in good condition.

- Monthly: Clean fixtures, clean tower ventilation ducts and heat sinks, ensure driver surface shows no overheating signs.

- Quarterly (3 Months): Check lubrication status of lifting mechanisms, clean rails, lubricate moving components, assess mechanical locking mechanisms, and check limit switch functionality.

- Every six months (6 months): Conduct a complete electrical check of the system (insulation, grounding, protection level of junction boxes), clean fans/exhaust ports, and check all fasteners.

- Yearly: Evaluate fixture/module replacement, inspect LED driver components, perform overall diagnostics on generators/power systems, update firmware and control software, replace oils and filters, and check for structural corrosion and coatings.

- Long-term (Every 2–3 years or as per manufacturer recommendations)

- Conduct a complete diagnosis of generator performance, assess the effects of wind load on the tower (structural safety, fatigue, bolt condition).

- Update firmware and control software to ensure stability and safety for remote/automated controls.

- Reassess power redundancy design and emergency power capabilities, upgrading as necessary.

3. Common Fault Troubleshooting (Quick Reference)

- No Output from Generator:

- Check fuel/power status, ensure the starter system is operational, and check fuel and coolant levels, battery condition, and fuses.

- Light Fixture Not Working:

- Confirm fixture wiring and module health, assess driver power status (check for overheating protection, ensure output is normal); if the driver is faulty, replace the driver or fixture module.

- Lifting Mechanism Stuck:

- Check lubrication points and rail cleanliness, assess mechanical locking mechanism status, inspect limit switches for sticking or malfunction; lubricate and replace parts as necessary.

- Control System Anomalies/Alarms:

- Restart the control system, check sensors and wiring; if necessary, update firmware and verify communication is normal.

Conclusion and Recommendations

Light Towers are critical for enhancing the efficiency and safety of nighttime operations worldwide. LED light towers significantly surpass traditional ones in energy efficiency, lifespan, and maintenance costs. Selection should comprehensively consider coverage area, power, mast height, wind load, and site conditions. Both purchasing and renting have applicable scenarios; it is advised to conduct a full lifecycle assessment based on project duration and maintenance capabilities.

Recommended Mobile Light Tower Products

Author and Authority Statement

This article was collaboratively written by the engineering and application teams at Luxman Light, whose members possess over ten years of combined experience in designing mobile lighting towers, on-site deployment, and global customer service across industries such as construction, energy, mining, and emergency rescue.