Why does solar street lamps design with internal hexagonal screws?

You may find that almost all solar street lamps are designed with inner hexagonal screws. Why are solar street lamp engineers so keen on using inner hexagonal screws for solar street lamps?

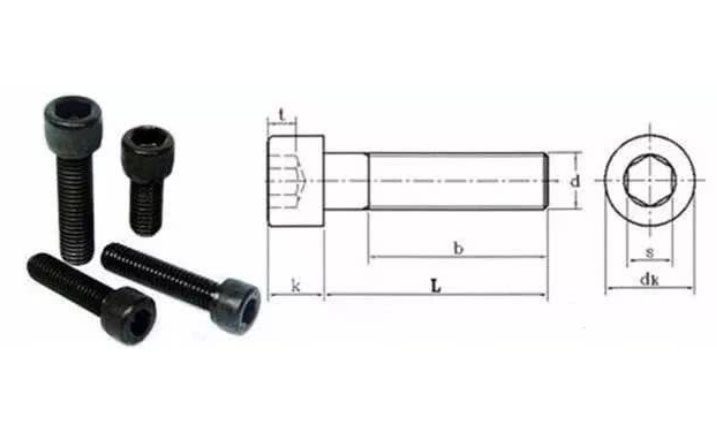

You will find that 99% of the assembled furniture bought online is hexagonal. The screw head of the inner hexagon screw is round outside and concave in the middle. Such a structure has obvious advantages.

1. Load bearing is greater.

It has six surfaces to bear the stress from a screwdriver, which is more capable of holding the screw than the one-sided screw and the cross-shaped screw with only two faces.

Note: The material of inner hexagonal bolt is generally made of stainless steel, carbon steel, and alloy steel, which are basically the same as other types of screws. The higher the performance grade, the greater the strength will do. When selecting the screw, the screw of suitable performance grade must be selected strictly according to the user requirements. The grade is different, and the price is also different.

2. It can be buried when treatment.

That is to say, the whole nut sinks into the inner part of the workpiece, which can keep the surface of the workpiece flat and beautiful.

3. Easy to installation.

Compared with the outer hexagon screw, the inner hexagon is suitable for more assembling occasions, especially narrow ones. Therefore, it is very convenient for assembling, repairing and maintenance.

4. Not easy to disassemble

Our common tools are movable wrenches, screwdrivers, and solid wrenches, while the removal of hexagonal bolts must use a special wrench, so it is not easy to disassemble, which is also an advantage.

Of course, if you may think you can design many kinds of weird structures, but the problem is that the special wrench is much more complicated to be manufactured.

As for this wrench issue, some people feedback that since the inner hexagonal bolt has the advantage of strength and is designed as a sinking hole, it is difficult to screw out in case of slippage, while the outer hexagonal bolt need common tools only to do so, why not design it as the following shape?

As you know, the outer hexagonal screw head is exposed. The wrench needs a certain space to screw out it. The sinking hole should be designed large or protruding, while the inner hexagonal only needs a small sinking hole.

Hence, actual application conditions and environment determines what type of screw must be used.

This article is originally created by LUXMAN LIGHT. Do not forward it without permission.

Recent updates:

<>How long do solar-powered street light last-LUXMAN Light

<>HOW TO MAINTAIN ALL IN ONE SOLAR STREET LIGHTS

For more information about green energy, lighting knowledge, please visit: