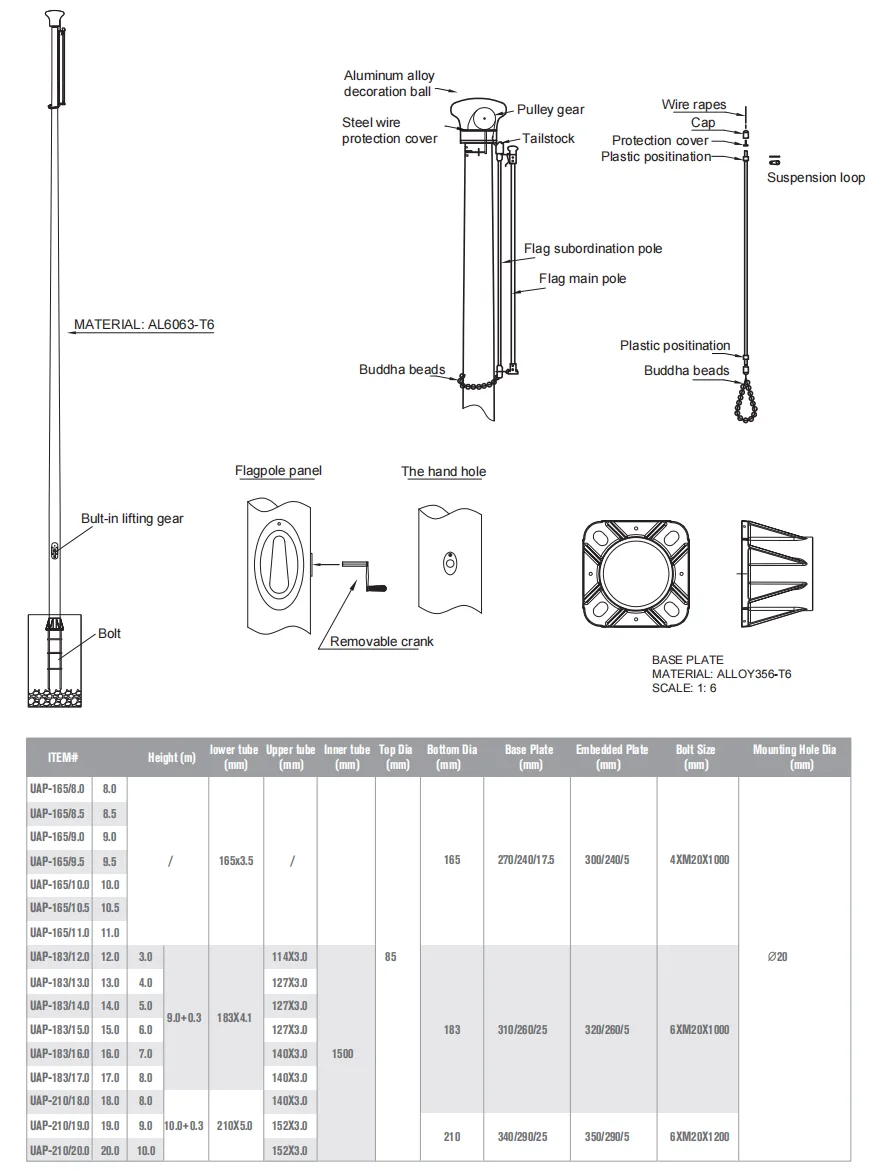

Fabricante de astas de bandera de aluminio – Luxman

El aluminio es uno de los materiales metálicos ecológicos más utilizados. Debido a sus excelentes prestaciones y ventajas, el aluminio se aplica ampliamente en campos como la aviación, la construcción y la automoción. El mástil de aluminio para banderas está fabricado con tubos de aleación de aluminio EN AW 6060/6063, mientras que la base de aluminio se fabrica mediante un proceso de fundición a baja presión con aleación A356, lo que lo convierte en un producto muy resistente y duradero.

Asta de bandera de aluminio Ventajas

La densidad de el aluminio es de 2,7 g/cm³es 1/3 del acero, por lo que el aluminio es mucho más ligero que el acero.

- Mecanizado sencillo (taladrar, cortar, fresar, punzonar, doblar, soldar, etc.).

- Con un rendimiento químico estable y reciclable, el aluminio es un metal ecológico respetuoso con el medio ambiente.

- Excelente resistencia a la corrosión.

- Excelente rendimiento para el acabado de superficies.

- La temperatura de fusión del aluminio es inferior a la del acero y reduce el coste de reciclado.

Astas de bandera de aluminio: calidad e integridad

- Nuestro anodizado mástiles de aluminio para banderas y nuestros postes satinados tienen una garantía de 25 años.

- Nuestros postes de aluminio pintados en polvo tienen una garantía de 5 años para la pintura a partir de la fecha de envío contra grietas, descascarillado, cambios excesivos de color y decoloración debidos a la exposición normal al clima, y de 25 años para los ejes de aluminio.

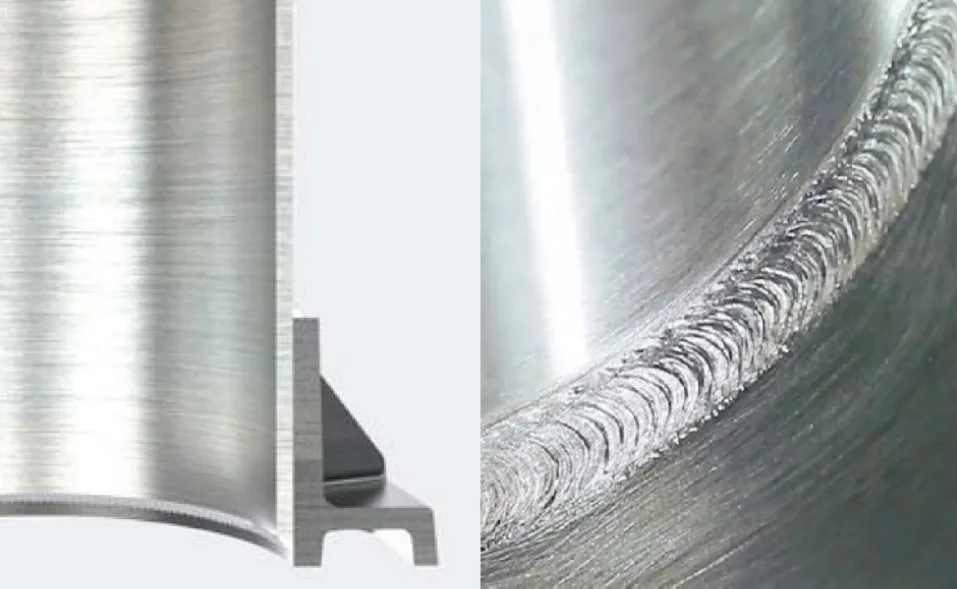

- Nuestros postes de aluminio se fabrican con soldaduras de calidad certificadas por la Oficina Canadiense de Soldadura. Nuestras capacidades de soldadura están a la altura de las normas internacionales más exigentes.

- Mediante el análisis de la sección se puede ver directamente la resistencia de la base y las soldaduras.

Acabado satinado cepillado –Cepillado satinado

Acabado satinado cepillado –Cepillado satinado

Colores anodizados – Negro

Colores anodizados –Bronce oscuro

Colores anodizados – Bronce medio

Colores anodizados – Bronce claro

Colores anodizados – Claro Natural

Colores de recubrimiento en polvo –Bronce oscuro

Colores de recubrimiento en polvo – Negro

Colores de recubrimiento en polvoBlanco

Colores de recubrimiento en polvo – Gris plata

Colores de recubrimiento en polvo –Verde oscuro

Transformación de la madera

Proceso de fabricación de mástiles de aluminio para banderas

1-Material

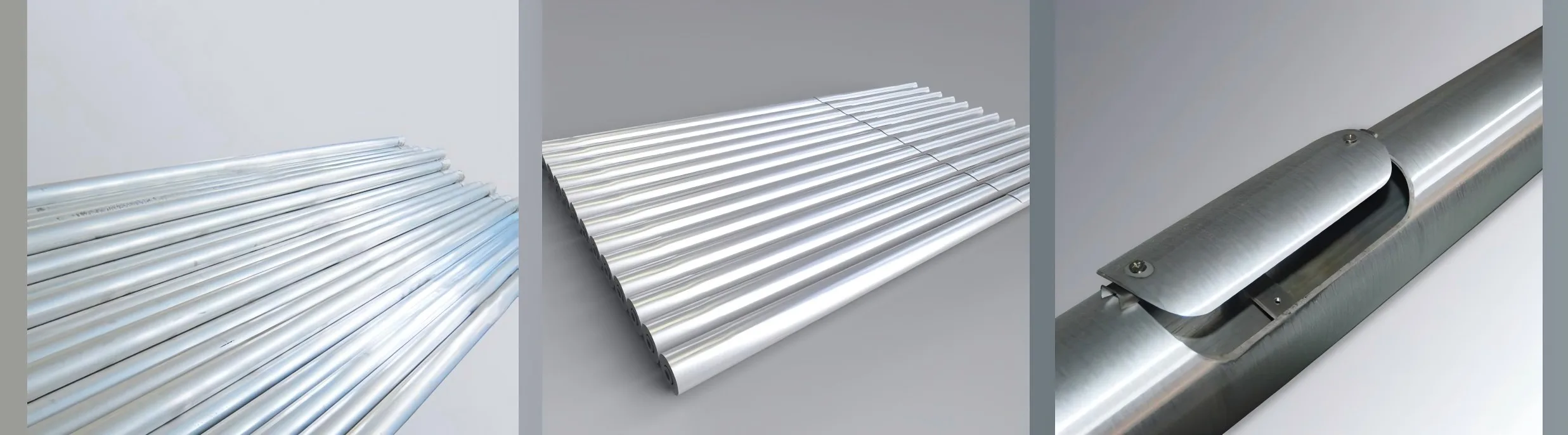

La materia prima para la hilatura es el tubo de aleación de aluminio 6063 / 6060. Esta aleación soporta la presión del viento, es muy resistente a la corrosión y tiene propiedades decorativas.

2-Girando

Mediante grandes equipos de hilatura CNC, las materias primas se transforman en formas cónicas o perfiladas.

3-Acceda a Puerta

Cada poste de aluminio tiene una cámara de cableado donde se instala la caja de conexiones. La tapa de la cámara de cableado se corta con láser o con una sierra especialmente diseñada. La cámara de cableado de las columnas de aluminio puede alcanzar una protección IP54.

Toma de tierra:

En el orificio hay un tornillo M8 para fijar el cable de toma de tierra.

Pernos para la tapa de la cámara de cableado:

La tapa de la cámara de cableado está asegurada por

pernos hexagonales de acero inoxidable para impedir la apertura de la puerta por personas no autorizadas.

4-Soldadura Para Base

La base de fundición de baja presión A356, y el tratamiento térmico T6, utilizamos equipos de soldadura automática para conectar la base y el poste. La calidad de la soldadura cuenta con la certificación de la Oficina Canadiense de Soldadura. En este proceso de soldadura de alta calidad, la fuerza de soldadura y cosméticos están garantizados.

5-T6 Calor Tratamiento

El calentamiento a 185-195 de temperatura durante 7-8 horas hace que la columna sea estable y la dureza

llega a 9-11HW.

6-Cepillo

Antes del acabado superficial, pulimos el poste para adaptarlo a los requisitos del cliente,

o chorro de arena para una superficie mate.

7-Superficie Acabado

Disponemos de cuatro acabados para los postes de aluminio:

1.Anodizado

El anodizado es un método electroquímico que crea una capa de óxido en la superficie del metal, adecuada para zonas costeras.

El recubrimiento anodizado estándar es de 15um, pero podemos ajustarlo según los requisitos del cliente.

2.Revestimiento de fluorocarbono

Se trata de un nuevo material de revestimiento con excelentes propiedades contra la decoloración, la corrosión del aire contaminado (lluvia ácida) y los rayos UV.

3. Recubrimiento en polvo

Recubrimiento en polvo de poliéster coloreado, colores brillantes, y no decoloración.

4.Impresión por transferencia de agua

Presión de agua para que el diseño de madera quede en relieve en la superficie del poste. Nota: Debido a la diferencia de material entre los postes, la base y el material de soldadura, es inevitable que se produzcan variaciones de color en el aluminio. Si desea garantizar la consistencia del color en la superficie de los postes, se recomienda el recubrimiento en polvo o el recubrimiento de fluorocarbono.

8-Pruebas

Morelux dispone de equipos completos de ensayo para postes, soportes y accesorios. Nuestra inspección incluye: ensayo de tracción, ensayo de límite elástico, ensayo de ductilidad, ensayo de oxidación/espesor de la película de pulverización, ensayo de adherencia, ensayo de dureza, la base de análisis y ensayo de imagen especular. Garantiza la calidad de cada poste de aluminio. Nuestro laboratorio químico está equipado para medir la calidad de los revestimientos anódicos. Nuestro laboratorio dispone de un espectrómetro avanzado que determina la composición cualitativa y cuantitativa de las mezclas de aleaciones, factor clave en la cualificación de las aleaciones de aluminio para el anodizado. La medición de la calidad de los revestimientos de óxido, la coloración, separada en intensidad de color espectral y nivel de superficie mate, se mide con un espectrómetro de alta calidad.

9-Embalaje

Morelux utiliza bolsas de nailon reforzadas, bolsas de burbujas y embalajes de cartón ondulado para proteger los postes durante el transporte.

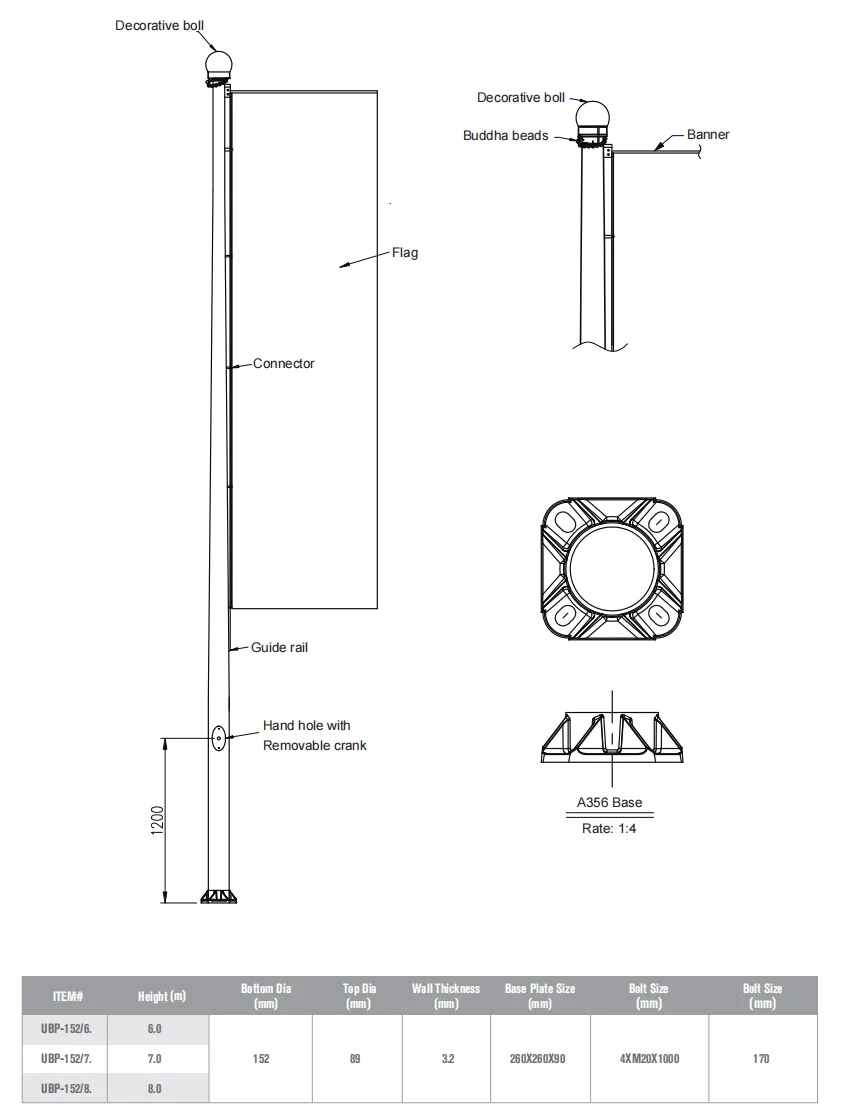

Asta de bandera de aluminio Característica del producto

Asta de bandera de aluminio tipo 1

Asta de bandera de aluminio tipo 2

Nuestros proyectos

Asta de bandera de aluminio para escuela/organismo gubernamental

Asta de bandera de aluminio para edificios comerciales

Asta de bandera de aluminio Park