1.アルミフラッグポールの概要

定義と利点

アルミ製フラッグポールは、一般的に押し出し/溶接アルミ合金またはセグメント組立構造で作られており、軽量、耐腐食性、容易な加工、審美的な魅力などの利点を備えています。自治体、企業、キャンパス、住宅、イベントなどで広く使用されています。

Luxmanの旗竿の素材は、主にEN AW 6060/6063アルミニウムで構成され、低圧鋳造のA356ベースによって補完され、様々な風荷重や使用状況に適応する高い構造強度と耐久性を提供します。

適用シーンファサードのメインフラッグ、セカンダリーフラッグ、中庭、道路標識、一時的なイベントサポートなど。

アルミ旗竿選定仕様参考表

国際単位参照表:高さ、底部直径、肉厚範囲、旗サイズ参照表。

| 高さ範囲 (m) | 底径範囲 (mm) | 肉厚範囲 (mm) | 適用シナリオ | 対応旗サイズ (m²) | 備考 |

|---|---|---|---|---|---|

| 1.5 – 3.0 | 38 – 76 | 1.5 – 3.0 | 小さな中庭、店先、個人住宅 | 0.5 – 1.2 | 住宅や小規模ビジネスのメインフラッグに最適 |

| 3.0 – 6.0 | 60 – 150 | 2.0 – 5.0 | 企業前、学校前、地域イベント前 | 1.2 – 2.5 | 安定性と美しさを備えた適度な高さ |

| 6.0 – 12.0 | 100 – 200 | 3.0 – 6.0 | 自治体、公共施設、景観サイン | 2.5 – 5.0 | 公共の場に適しており、安定性と美観のバランスが求められる |

| 12.0 – 15.0 | 150 – 300 | 4.0 – 8.0 | 主要な広場、記念建造物、象徴的な建築物 | 5.0 – 10.0 | 耐風荷重が強く、強風地域に適している。 |

| 15.0 – 30.0 | 200 – 400 | 6.0 – 12.0 | 大きな広場、都市遺跡、記念建築 | 10.0 – 20.0 | 高強度設計、詳細な構造検証が必要 |

フィートと国際単位参照表:高さ、旗の大きさ、適用シナリオ参照表。

| 高さ範囲(FT) | 高さ範囲 (M) | 旗のサイズ(FT) | フラッグサイズ(M) | フラッグ面積 (FT²) | フラッグ面積 (M²) | 適用シナリオ | 備考 |

|---|---|---|---|---|---|---|---|

| 5 | 1.5 | 2.5 × 4 | 0.76 × 1.22 | 10 | 0.929 | 住宅地/小型店舗、壁面設置、ファサードの識別や中庭の装飾に適している。 | スモールセッティングに最適 |

| 6 - 8 | 2.0 | 3 × 5 | 0.91 × 1.52 | 15 | 1.394 | 店頭、中規模オフィスビルのエントランス、学校・地域イベントのエントランス、展示ブース | ミディアムセッティングに最適 |

| 15 | 4.5 | 3 × 5 | 0.91 × 1.52 | 15 | 1.394 | 企業前、屋外イベント入口、商店街の看板、展示会の背景など | 企業イベントに最適 |

| 20 | 6.0 | 3 × 5 | 0.91 × 1.52 | 15 | 1.394 | 本社外観、大型イベントエントランス、ショッピングモール/アミューズメント施設のファサード | 企業イベントに最適 |

| 25 | 7.5 | 4 × 6 | 1.22 × 1.83 | 24 | 2.230 | 大きな公共施設、都市の広場、スタジアムのファサード、記念建築のモニュメント展示 | 大規模なセッティングに最適 |

| 30 | 9.0 | 5 × 8 | 1.52 × 2.44 | 40 | 3.716 | 大型イベント、展示センター、スタジアムのファサード、コンサート会場 | 大規模イベントに最適 |

| 40 | 12.0 | 6 × 10 | 1.83 × 3.05 | 60 | 5.574 | 政府/自治体の建物、広場の重要な記念行事、都市のランドマーク、儀式的行事 | 大切な日にふさわしい |

| 50 | 15.0 | 8 × 12 | 2.44 × 3.66 | 96 | 8.919 | 国家レベルの大きなイベント、多国籍の活動、ランドマークとなる建物の大きな案内標識 | 重要なイベントや象徴的な行事に最適 |

| 60 | 18.0 | 10 × 15 | 3.05 × 4.57 | 150 | 13.935 | 主要なスポーツイベント、都市のランドマーク、見本市のメインフラッグ | 重要なイベントや象徴的な行事に最適 |

| 70 | 21.5 | 12 × 18 | 3.66 × 5.49 | 216 | 20.067 | 超大型会場、都市間イベント、都市景観ランドマーク | 重要なイベントや象徴的な行事に最適 |

| 80 | 24.5 | 15 × 25 | 4.57 × 7.62 | 375 | 34.839 | 世界的なイベント、ナショナル・デーのパレード、重要な国際的活動、主要なランドマーク | 大規模なセッティングに最適 |

| 90 | 27.5 | 15 × 25 | 4.57 × 7.62 | 375 | 34.839 | 極めて大規模な公的イベント、国際的な競技会、広く人目に触れる場所 | 大規模なセッティングに最適 |

| 100 | 30.5 | 15 × 25 | 4.57 × 7.62 | 375 | 34.839 | 極めて大規模な公的イベント、国際的な競技会、広く人目に触れる場所 | 大規模なセッティングに最適 |

2.コアの利点

アルミ製フラッグポールは、その軽量性と高強度の黄金比により、現代のフラッグポールの主流となっています。その核心的な利点は、材料特性の深い統合とシーンへの適応性にあります。伝統的な金属材料に比べ、アルミニウム合金の密度は鋼鉄の3分の1しかないにもかかわらず、陽極酸化処理によって緻密な保護膜を形成することができ、沿岸部の湿度の高い環境や工業地帯で15年以上の耐久性を実現し、錬鉄製の旗竿の平均寿命である5年をはるかに上回っています。

また、設置やメンテナンスの経済的な面でも優れています。モジュール設計により、10メートルの旗竿1本を3~4分割に分解して運搬できる。陽極酸化処理による鏡面効果は、四半期に一度の水洗いで新しい外観を保つことができ、再塗装にかかる人件費を節約できます。この「永続的」な特性により、アルミ製フラッグポールは屋外のプロモーションや展示会で特に役立ちます。水を充填したPEベースと組み合わせることで、耐風性レベル6を達成し、携帯性と安定性のバランスを完璧に保つことができます。

美観とカスタマイズの可能性は、さらにその用途を広げます。政府機関の銀白色艶消し仕上げから商業活動のカラフルな粉体塗装まで、アルミ製旗竿は電気泳動や溶射などの工程を経て、RALカラーチャートに一致するフルカラーのカスタマイズが可能です。最近の祝賀会では、主催者が100本のアルミ製旗竿をグラデーションのカラーマトリックスに組み合わせ、0.2mmの加工精度で規律正しい視覚的配置を実現しました。この品質により、アルミニウム製旗竿は、工業規格と芸術的表現が融合し、本格的な国旗掲揚の儀式にも、インスタレーション・アートの運搬役にもなる。

旗竿のサイズと高さの範囲の決め方

一般的な高さオプション(市場規範に基づく)

- スモール/コートヤード 約2.0m(約6.5フィート) - 約3.0m(約10フィート)

- 商業/ユニット 約3.0m(約10フィート) - 約6.0m(約20フィート)

- 標準的な自治体/景観:

- 約6.0メートル(約20フィート)

- 約9.0メートル(約30フィート)

- 約12.0メートル(約40フィート)

- 約15.0メートル(約50フィート)

- ハイポール/記念

- 約18.0メートル(約60フィート)

- 約20.0メートル(約65フィート)

- 約25.0メートル(約80フィート)

- 約30.0メートル(約100フィート)

直径と肉厚(高さ/風速設計により異なる)

- 小型(≦約3m):底径約 38~76mm(約1.5~3.0インチ)肉厚 1.5~3.0mm(約0.059~0.118インチ)

- ミディアム(約3~12m):底の直径 60~150mm(約2.4~5.9インチ)肉厚 2.0~5.0mm(約0.079~0.197インチ)多くの場合、円錐/セグメント構造

- 高さ(>約12メートル):底部直径約 150-400mm以上(約5.9-15.7インチ)肉厚 4.0~12.0mm(約0.157~0.472インチ)風荷重の考慮と構造的検証が必要

具体的な比較とカスタマイズ

- 実際の直径/壁の厚さは、旗の面積、風域区分、暴露環境、安全係数に基づいて設計する必要があります。メーカーは通常、「高さごとの旗竿の直径」の比較表やカスタマイズプランを提供しています。

旗竿の表面処理と耐久性の選び方

4種類の表面処理オプションがある:

陽極酸化処理

- 標準膜厚:15μm、沿岸部に適し、耐食性と表面硬度を効果的に高める。

- カラーオプション:ブラック、ダークブロンズ、ミディアムブロンズ、ライトブロンズ、透明ナチュラルカラーなど。

- 特徴モダンなシルバーグレーの外観で、ISO 7599規格に適合。

フルオロカーボンコーティング

- 特徴耐退色性、耐汚染性、耐紫外線性に優れ、海洋環境に適している。

- 製品の寿命を効果的に延ばすことができます。

パウダーコーティング

- 特徴豊かな色彩、優れた耐候性、高い色持ち。

- カラーオプション:ブラック、ホワイト、シルバーグレー、ダークブロンズ、ダークグリーンなど、複数のカラーをご用意。

- 通常、Qualicoatのような検査システムによって認証され、コーティングの品質が保証される。

水転写印刷

- 特徴木目や他のテクスチャのデザインを達成することができ、外観の多様性と審美的な魅力を高める。

色のばらつきと一貫性

- カラーバリエーションノート:陽極酸化処理は、ロットの違いにより色にばらつきが生じることがあります。厳密な一貫性が必要な場合は、粉体塗装またはフッ素樹脂塗装をお勧めします。

- 環境適応性:沿岸環境では、よりグレードの高い表面処理オプションを優先することが推奨される。

耐久性とメンテナンス

- 沿岸部や腐食性の高い環境では、定期的な保守・点検とともに、多層保護(陽極酸化処理と粉体塗装の組み合わせなど)を推奨する。

- 塗膜検査には、膜厚、塩水噴霧試験、密着性などが含まれる。製品の品質を保証するために、品質検査報告書の提出を推奨する。

Luxmanの表面処理オプション

ラックスマンは、以下のようなさまざまな表面処理オプションを提供しています:

- 陽極酸化処理:標準的なアルマイト層は約15μmで、必要に応じて調整可能。

- パウダーコーティング:多彩なカラーバリエーションと高い耐候性を提供。

- コーティングの組み合わせ:陽極酸化処理と他のコーティングを組み合わせることで、製品の寿命を延ばすことができる。

- 水転写印刷やその他のプロセスは、特定の色効果を得るために使用されるが、アルマイト処理に関連する潜在的な自然の色の違いや材料の違いに注意を払う必要がある。

旗竿と旗のサイズの計算方法

旗竿と旗の比率が推奨値を満たしていないと、不格好で見栄えの悪い外観になります。したがって、旗竿の美観を保ち、旗竿と旗の比率のガイドラインを守るためには、適切な旗のサイズを選ぶことが重要です。

最も簡単な方法は、旗竿の高さや旗のサイズの計算機などの計算機を使うことです: https://actionflag.com/blogs/american-flag-insights-and-updates-from-action-flag/flag-size-calculator-for-perfect-proportions

アメリカ国旗の場合は、ポールの高さの4分の1から3分の1の大きさにします。適切な旗のサイズは、特定の設置状況によって異なる場合があることに注意することが重要である。例えば、地面に設置する場合と壁に取り付ける場合とでは、必要な旗のサイズが異なる場合がある。

上記のセレクション仕様書をご参照ください:

- 壁掛け式、高さ1.5m、旗のサイズ2.5×4フィート、旗の面積0.929m²。

- 壁掛け式、高さ2.0m、旗サイズ3×5フィート、旗面積1.394m²。

- 地上;高さ4.5メートル(15′);旗のサイズ3×5フィート;旗の面積1.394 m²

- 地上;高さ6.0メートル(20フィート);旗のサイズ3×5フィート;旗の面積1.394平方メートル

- 地上;高さ7.5メートル(25フィート);旗のサイズ4×6フィート;旗の面積2.230平方メートル

- 地上;高さ9.0メートル(30フィート);旗のサイズ5×8フィート;旗の面積3.716平方メートル

- 地上;高さ12.0メートル(40フィート);旗のサイズ6×10フィート;旗の面積5.574平方メートル

- 地上;高さ15.0メートル(50′);旗のサイズ8×12フィート;旗の面積8.919 m²

- 地上;高さ18.0メートル(60フィート);旗のサイズ10×15フィート;旗の面積13.935平方メートル

- 地上;高さ21.5m(70′);旗のサイズ12×18フィート;旗の面積20.067m²。

- 地上;高さ24.5m(80′);旗の大きさ15×25フィート;旗の面積34.839m²。

- 地上;高さ27.5m(90′);旗の大きさ15×25フィート;旗の面積34.839m²。

- 地上;高さ30.5m(100′);旗の大きさ15×25フィート;旗の面積34.839m²。

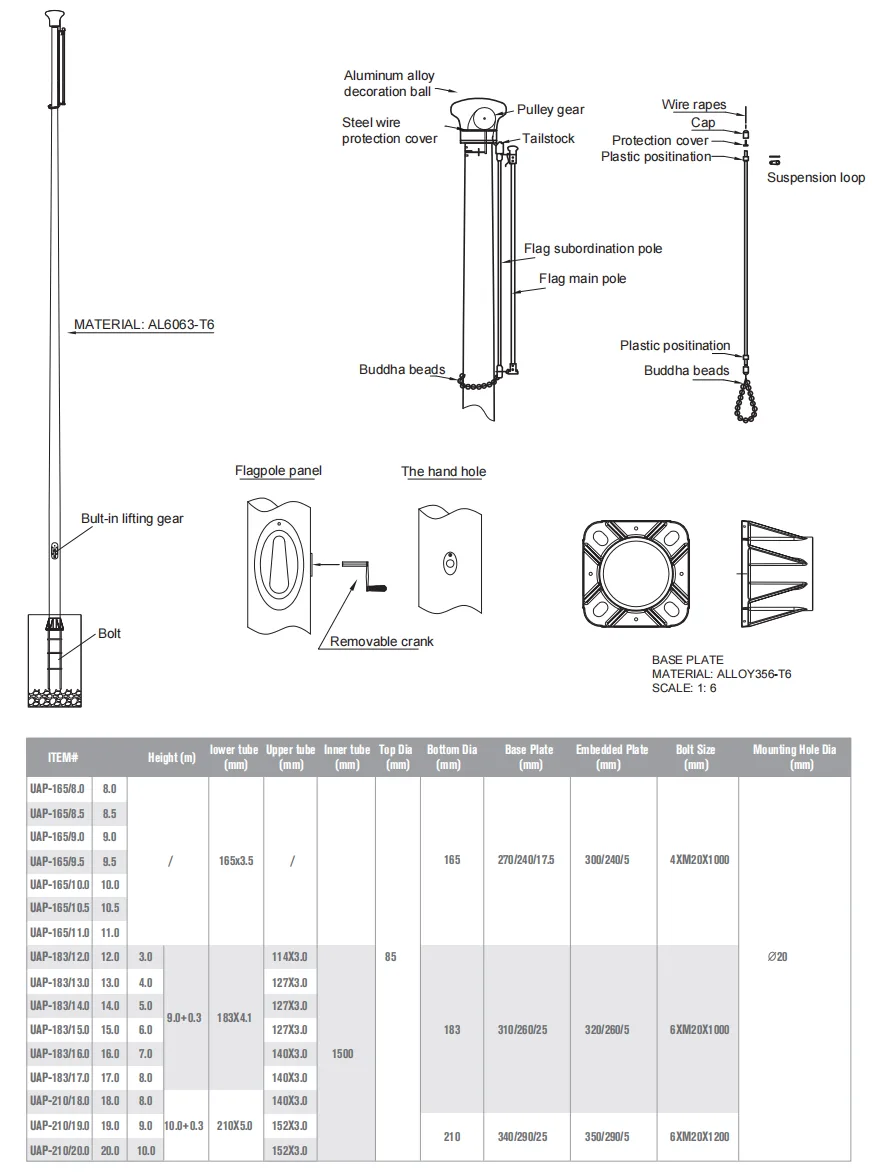

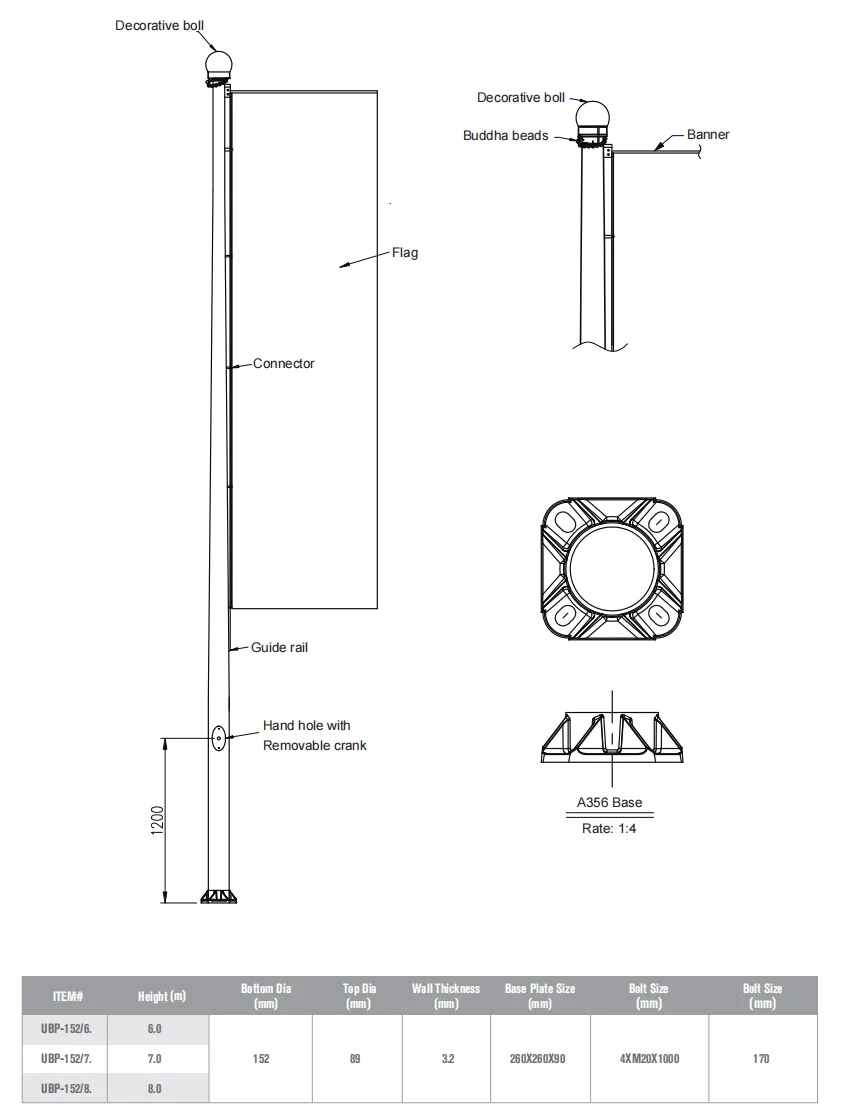

構造用アクセサリーとシステム

タイプ1

タイプ2

フラッグポール・サプライヤーの決め方:譲れない基準

- 製造認証

GB/T 3190-1996(アルミニウム合金)およびISO 5817(溶接品質)標準に準拠していることを確認します。当社の工場は、グレードAの溶接基準を維持し、超音波検査により、重要な接合部の気孔率が<0.1mmであることを保証します。 - エンジニアリング能力

風荷重の計算にはSAP2000有限要素解析の使用を義務付けています。例えば、私たちが設計した屋根に取り付けられた旗竿の応力比は0.266で、構造安全基準値の0.6をはるかに下回っています。 - 試験プロトコル

当社の品質管理には以下が含まれる:- 100%寸法検査(公差±0.5mm)

- 48時間塩水噴霧試験(ASTM B117規格)

- 設計風速125%での動的荷重試験。

フラッグポールに関するよくある質問(FAQ)

Q: アルミ製旗竿の一般的な高さと直径の組み合わせは?

A: 一般的な高さは3、6、9、12、15、18、20、25、30m。直径と壁の厚さは、メーカーの仕様に基づき、高さと風荷重によって異なる。

Q: アルマイト処理と粉体塗装のどちらが耐久性がありますか?

A: アルマイト処理は耐摩耗性と耐食性に優れ、粉体塗装は多彩な色彩と耐候性に優れています。沿岸環境では、通常、よりグレードの高いコーティングの組み合わせが選択され、必要に応じて追加の保護が施されます。

Q:風荷重はどのように考慮すべきですか?

A: 風圧の計算は、現地の風速基準(ASCE 7 / EN 1991-1-4など)に基づき、旗の投影面積と設置高さを組み合わせてモーメントとたわみをチェックし、強度と剛性の要件を満たすプロファイルを選択する必要があります。

Q: カスタマイズやサンプルはありますか?

A: はい、高さ、旗の幅、風速等級、表面処理、数量の要件をご提出ください。

Q: サイズ表と重量表のダウンロードリンクを教えてください。

A: はい。 お問い合わせ.

参考文献と権威ある情報源

- - ASTM International - ASTM B221:アルミニウムおよびアルミニウム合金押出棒、棒、線、プロファイル、管の標準仕様書。 https://www.astm.org/standards/b221.htm

- - 欧州標準化委員会 - EN 1991-1-4:構造物への作用 - 一般作用 - 風作用. https://eurocodes.jrc.ec.europa.eu/showpage.php?id=138

- - ISO 7599:アルミニウム及びその合金の陽極酸化-陽極酸化皮膜の一般仕様。 https://www.iso.org/standard/63262.html

- - ASCE - ASCE/SEI 7: 建築物およびその他の構造物の最小設計荷重および関連基準。 https://law.resource.org/pub/us/cfr/ibr/003/asce.7.2002.pdf

- - 材料密度と特性の参照:MatWeb 材料特性データ - アルミニウムおよびアルミニウム合金. https://www.matweb.com/

- - 塗装/耐候性の基準:粉体塗装アルミニウムのクオリコート塗装基準。 https://www.qualicoat.net/main/specifications.html

注:上記の規格および仕様は、設計の手引きおよび検証のためのものであり、特定のプロジェクトでは、各国/地域の義務的な規制および検査報告書に準拠する必要があります。プロジェクト・パラメーターに基づく詳細な選定計算、サイズ表、重量表(CAD/BIMを含む)については、下記まで情報をお送りください。 お問い合わせ (プロジェクトの位置、設計風速、旗の幅、希望する高さを示す)。