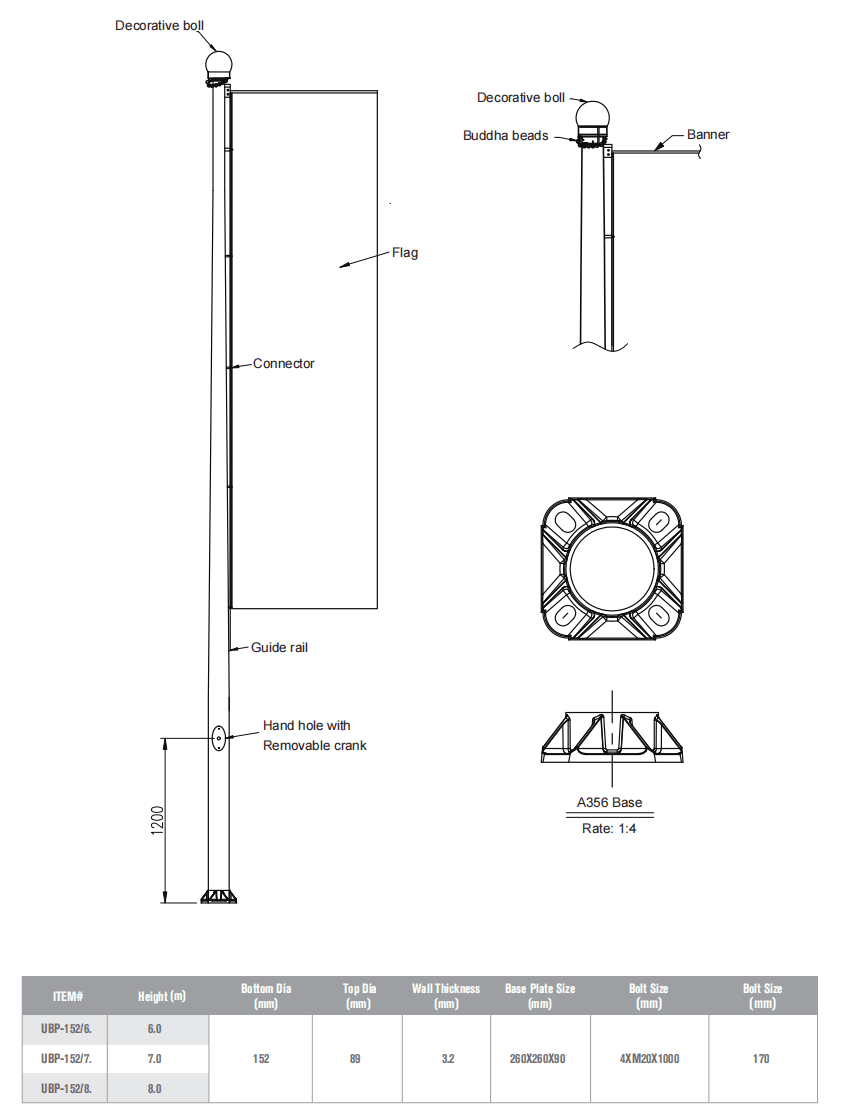

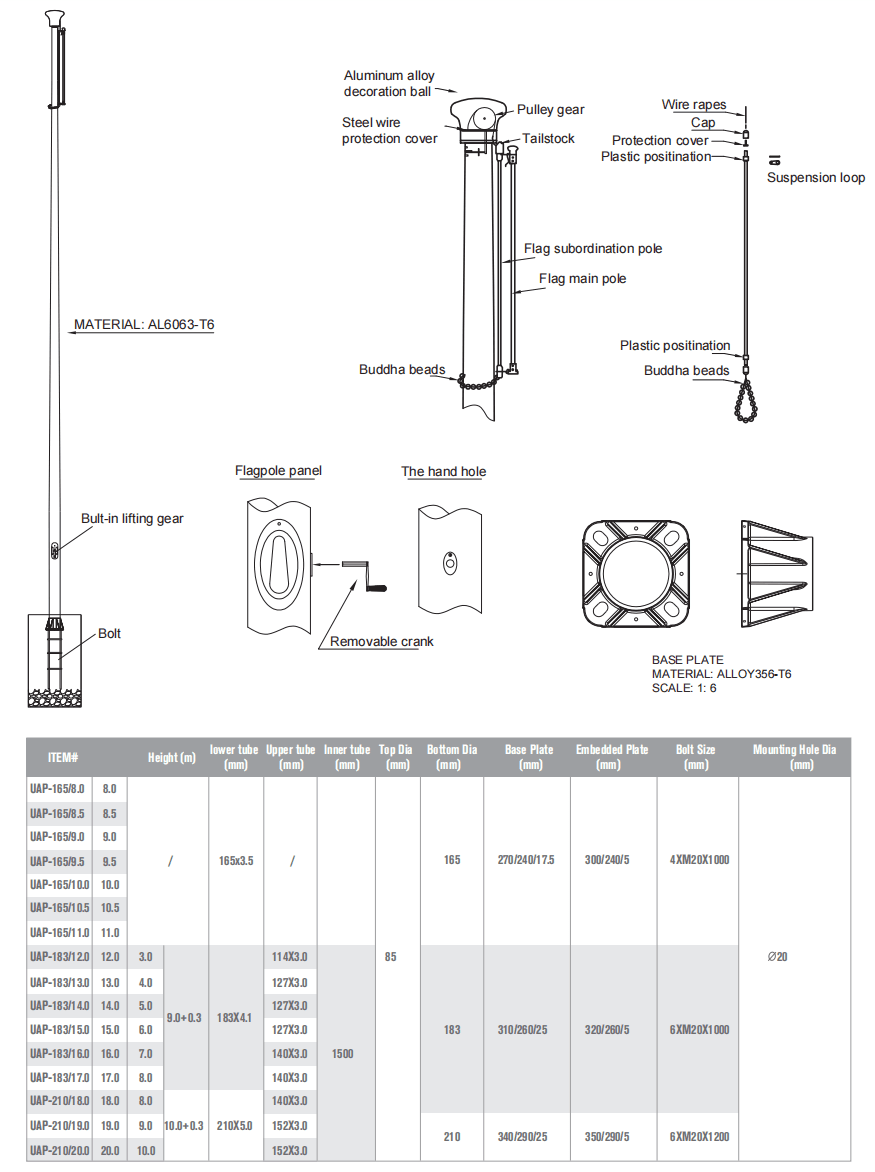

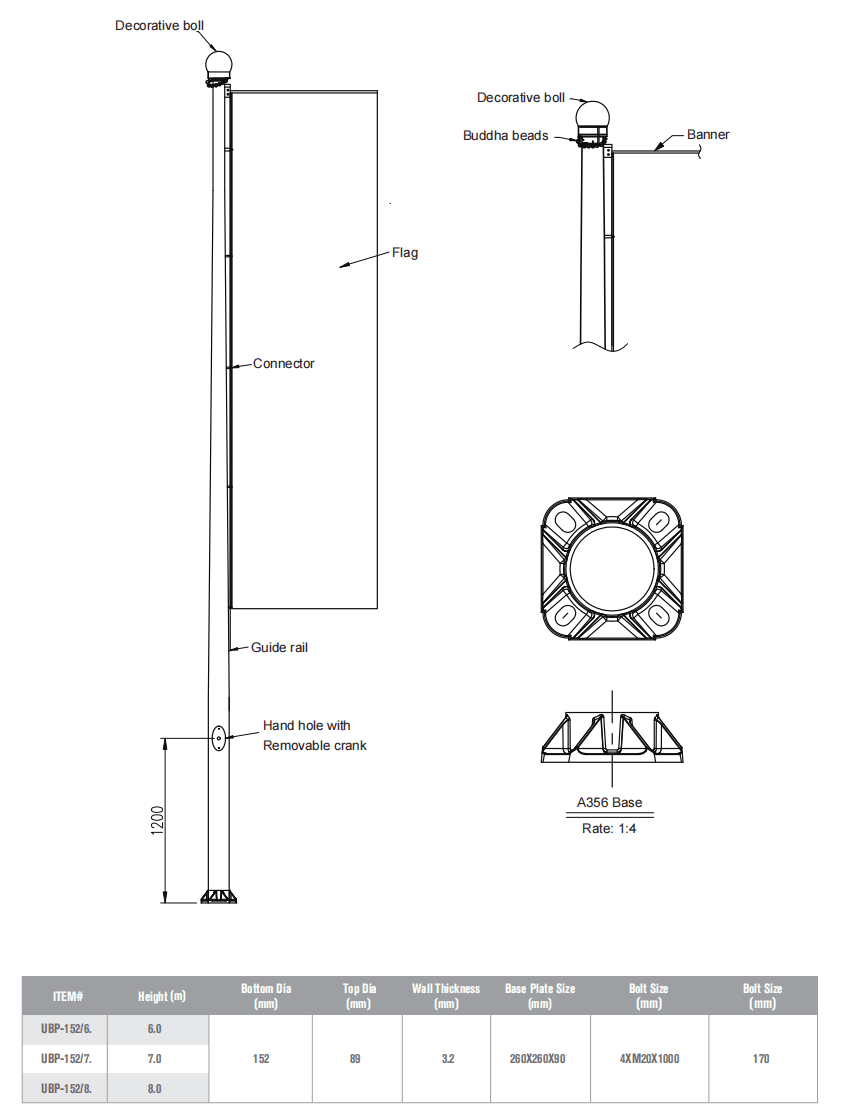

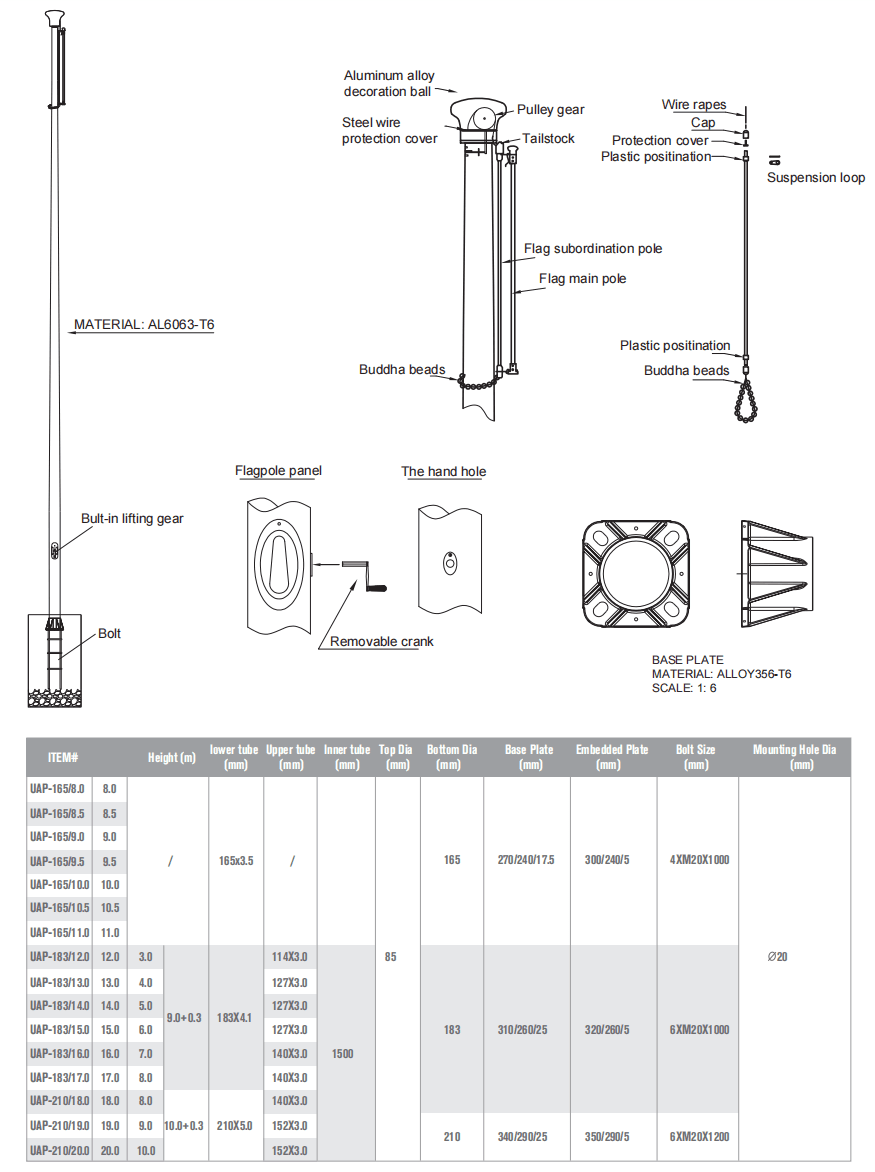

5. Structural Accessories and Systems

Style 2

How to Determine Flag Pole Suppliers: Non-Negotiable Standards

- Manufacturing Certification

Ensure compliance with GB/T 3190-1996 (Aluminum Alloy) and ISO 5817 (Welding Quality) standards. Our factory maintains Grade A welding standards, and ultrasonic testing ensures that the porosity rate of critical joints is <0.1mm.

- Engineering Capability

Require the use of SAP2000 finite element analysis for wind load calculations, for example our roof-mounted flag pole design’s stress ratio is 0.266, far below the structural safety threshold of 0.6.

- Testing Protocol

Our quality control includes:

- 100% size inspection (tolerance ±0.5mm)

- 48-hour salt spray test (ASTM B117 standard)

- Dynamic load testing at 125% design wind speed.

Common Questions About Flag Poles (FAQ)

– Q: What are the common height and diameter combinations for aluminum flag poles?

– A: Common heights cover 3, 6, 9, 12, 15, 18, 20, 25, 30 m; diameter and wall thickness vary according to height and wind load, based on the manufacturer’s specifications.

– Q: Which is more durable, anodizing or powder coating?

– A: Anodizing is wear-resistant and has strong corrosion resistance; powder coating offers diverse colors and good weather resistance. For coastal environments, higher-grade coating combinations are typically chosen and additional protection is applied when necessary.

– Q: How should wind loads be considered?

– A: Wind pressure calculations should be based on local wind speed standards (ASCE 7 / EN 1991-1-4, etc.), combined with the projected area of the flag and installation height for moment and deflection checks, selecting profiles that meet strength and stiffness requirements.

– Q: Do you provide customization and samples?

– A: Yes, please submit height, flag width, wind speed grade, surface treatment, and quantity requirements, and we can provide sample plans and quotes.

– Q: Can you provide a download link for size and weight tables?

– A: Yes, please contact [email protected].

References and Authoritative Sources

– ASTM International — ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes. https://www.astm.org/standards/b221.htm

– European Committee for Standardization — EN 1991-1-4: Actions on structures — General actions — Wind actions. https://eurocodes.jrc.ec.europa.eu/showpage.php?id=138

– ISO 7599: Anodizing of aluminum and its alloys — General specifications for anodic oxidation coatings. https://www.iso.org/standard/63262.html

– ASCE — ASCE/SEI 7: Minimum Design Loads and Associated Criteria for Buildings and Other Structures. https://law.resource.org/pub/us/cfr/ibr/003/asce.7.2002.pdf

– Material Density and Properties Reference: MatWeb Material Property Data — Aluminum and Aluminum Alloys. https://www.matweb.com/

– Coating/Weather Resistance Reference: Qualicoat coating standard for powder-coated aluminum. https://www.qualicoat.net/main/specifications.html

Note: The above standards and specifications are for design guidance and verification; specific projects should comply with mandatory regulations and inspection reports for the respective country/region. For detailed selection calculations, size tables, or weight tables (including CAD/BIM) based on project parameters, please send information to [email protected] (indicating project location, design wind speed, flag width, and desired height).