Aluminum Flag Pole Production Process

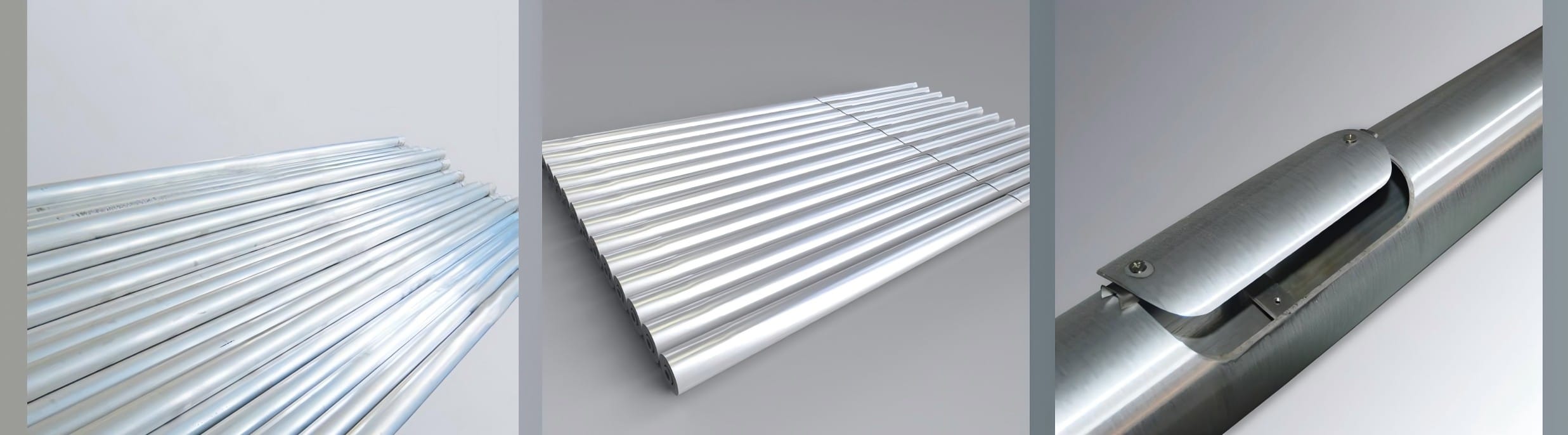

1-Material

Raw materials for spinning are aluminium alloy 6063 / 6060 tube. This alloy can sustain wind pressure, is highly resistant to corrosion and has decorative properties.

2-Spinning

Using large CNC spinning equipment, the raw materials are made into conical or profiled shapes.

3-Access Door

Each aluminium pole has a wiring chamber where the connection box is installed. The wiring chamber cover is laser cut or by specially designed saw. The wiring chamber of aluminium columns can achieve IP54 protection.

Earthing:

There is M8 bolt in the hole for fastening the earth grounding wire.

Bolts for Wiring Chamber Cover:

The wiring chamber cover is secured by

hexagonal stainless steel bolts to prevent door opening by unauthorized persons.

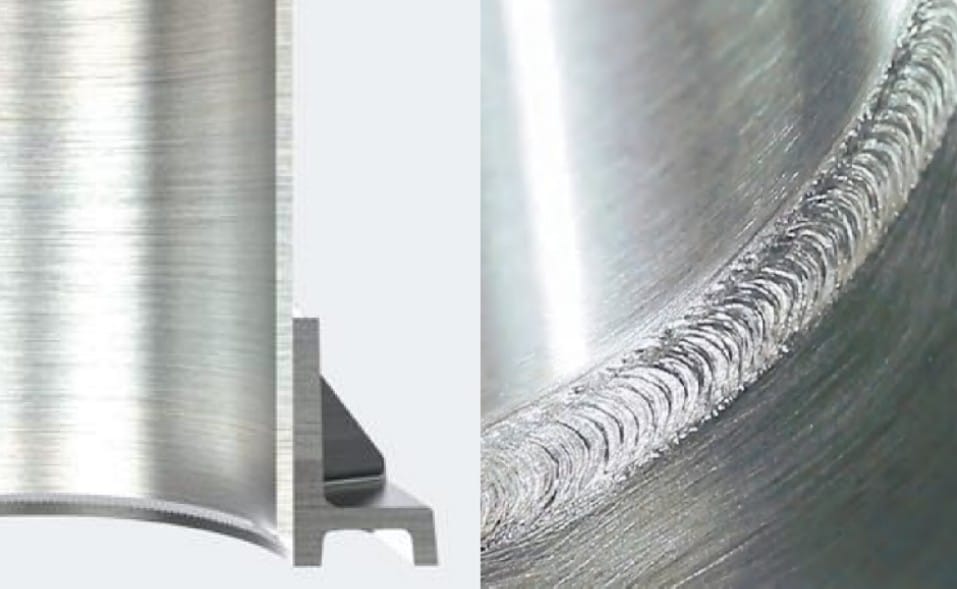

4-Welding For Base

The A356 low pressure casted base, and T6 heat treatment, we use automatic welding equipment to connect base and pole. The welding quality has the Canadian welding Bureau certification. In this high quality welding process, the welding strength and cosmetics are guaranteed.

5-T6 Heat Treatment

Heating at 185-195 temperature for 7-8 hours makes the column stable and the hardness

reaches 9-11HW.

6-Brush

Before surface finish, we polish the pole in to fit customer requirements,

or sand blasting for matte surface.

7-Surface Finishing

We have four finishes for aluminium poles:

1.Anodizing

Anodizing is an electrochemical method which creates an oxide layer on the surface of the metal, which is suitable for coastal areas.

The standard anodizing coating is 15um, but we can adjust according to custorm’serequirement.

2.Fluorocarbon coating

A new coating material, it has excellent anti-fade, anti polluted air (acid rain) corrosion, and anti-UV ability

3. Powder coating

Colored polyester powder coating, bright colors, and non-fading.

4.Water transfer printing

Water pressure to make the wood design embossed on the pole surface. Notice: Anodizing inherently results in color variation on aluminium as the material difference between the poles,the base and the welding material, it is inevitable. If you want to ensure the color consistency on surface of poles. powder coating or fluorocarbon coating is recommended.

8-Testing

Morelux has complete testing equipment for poles, brackets and accessories. Our inspection includes: tensile testing, yield strength test, ductility test, oxidation /spray film thickness test, adhesion test,hardness test, the base of mirror image analysis and testing. Ensures thequality of each aluminium pole. Our chemical laboratory is equipped for measuring the quality of anodic coatings. Our laboratory has an advanced spectrometer which determines the qualitative and quantitative composition of alloy mixtures which is key factor in the qualification of aluminium alloys for anodizing. The measurement of the quality of oxide coatings, colouring, separated into spectral colour intensity and matte surface level is measured by a high quality spectrometer.

9-Packaging

Morelux uses reinforced nylon bag, bubble bag and corrugated packaging, tomulti layeringthe light pole whichprotects the poles during transportation.

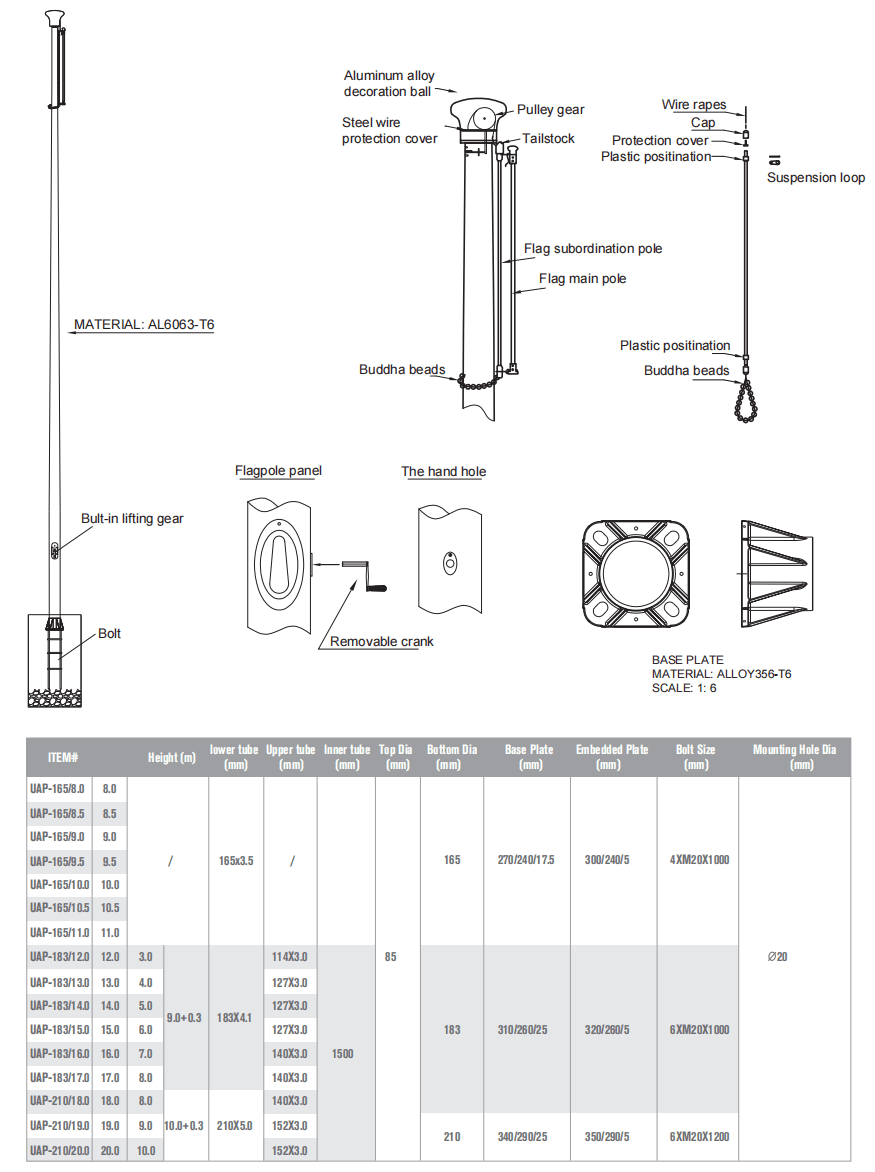

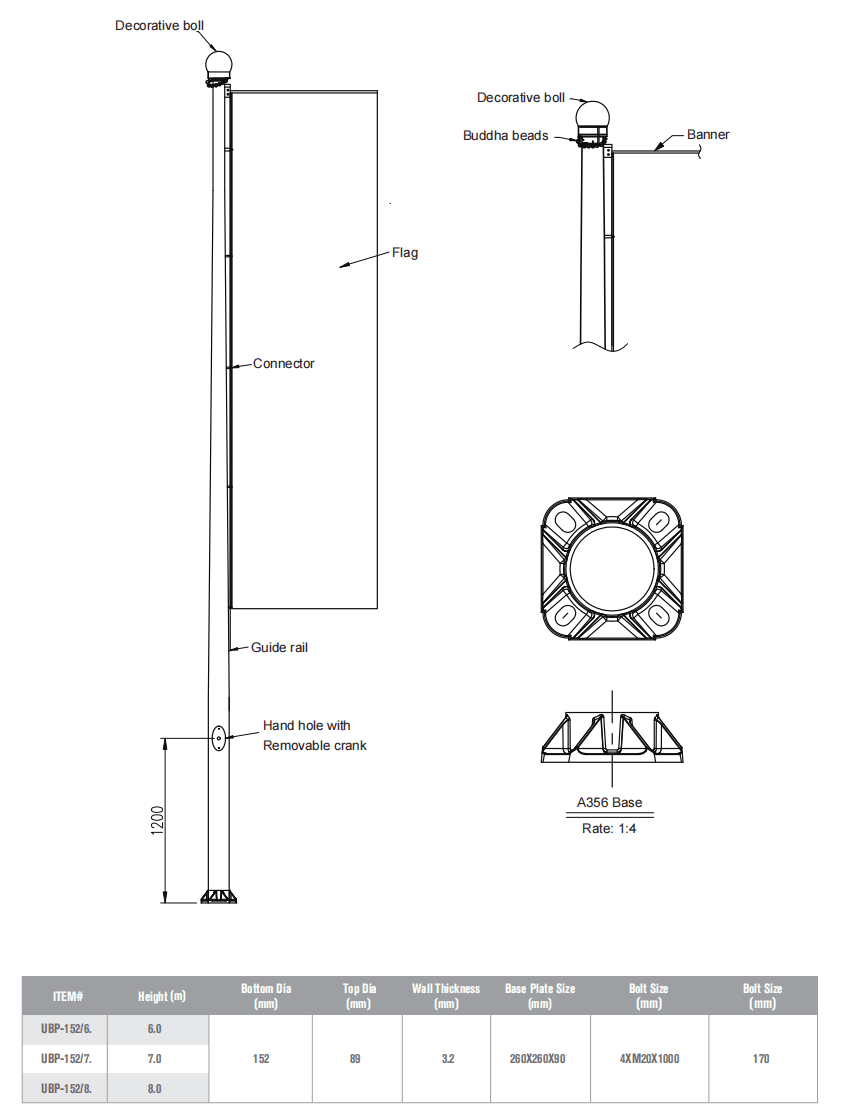

Aluminum Flag Pole Product Feature